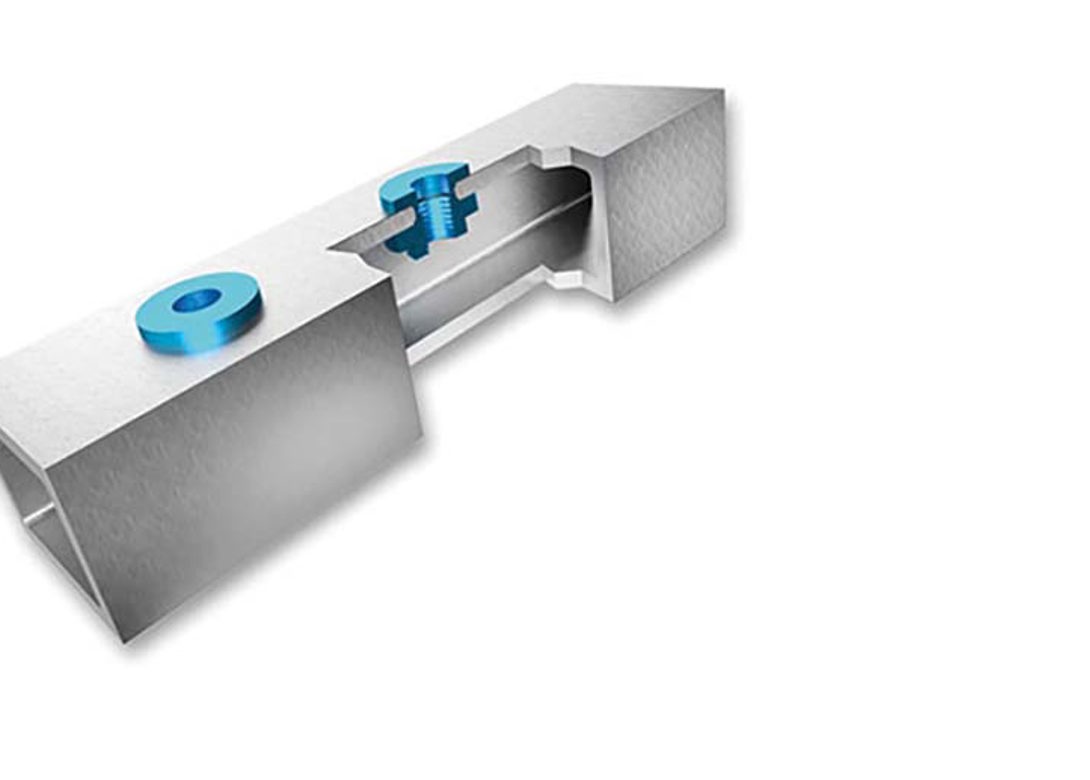

Setting high strength connections in closed profiles requires special solutions, which is why MDS AUTORIV offers a patented setting process for such applications. Its combination of press-in nut and washer was specially developed for series production.

Often used in practice in the field of eMobility, for example in the battery trays of electric vehicles, this connection is also of great benefit for crash elements, module carriers and in commercial and agricultural machinery construction. Furthermore, the combination is often used as a stop surface and is also suitable as a chemical insulator.

“Basically, this combination offers advantages when used in hard-to-reach places and with limited installation space, for example in closed profiles and extruded profiles,” points out MDS AUTORIV. The connection can be set with the AUTORIV procedure without having to open the profiles. The combination is also ideal for components with undercuts or overlaps.

The establishment of such a connection usually requires several work steps and is therefore quite cost intensive. With the automated use of the press-in nut washer combination, the setting process can be carried out in a single work step. In addition, several connections can be set at the same time. The streamlining of the manufacturing process therefore offers some potential for cost savings – such as shorter lead times and lower logistics costs.

“The press-in nut washer combination offers many advantages compared to a conventional blind rivet nut: Strength of the connection, high pulling force, higher torque and larger contact surface. The high strength connection is independent of the screw connection,” explains MDS AUTORIV.

The press-in nut washer combination also shows no setting behaviour. It is preferably used in aluminium profiles with a wall thickness of 4.5mm or more. The press-in nut can also be used as a single part without spacers for sheet metal thicknesses from 2mm. The advantages here are the low overall height and a flush surface.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.