China boasts the longest high-speed rail network in the world at over 25,000km – and the country is investing even further in the expansion of the rail system. In order to ensure the safety of people, and technology in the process, older tracks are currently being refurbished and reinforced as a preventative measure – using over 250,000 cartridges of the fischer epoxy mortar FIS EM 390 S.

China is the land of the ‘fast track’ on longer routes. With the ever expanding high-speed rail network, the country intends to link large cities together, increase traffic capacity and strengthen the domestic economy by establishing connections to neglected regions. Despite the focus on ‘faster’ and ‘further’, safety should not be overlooked.

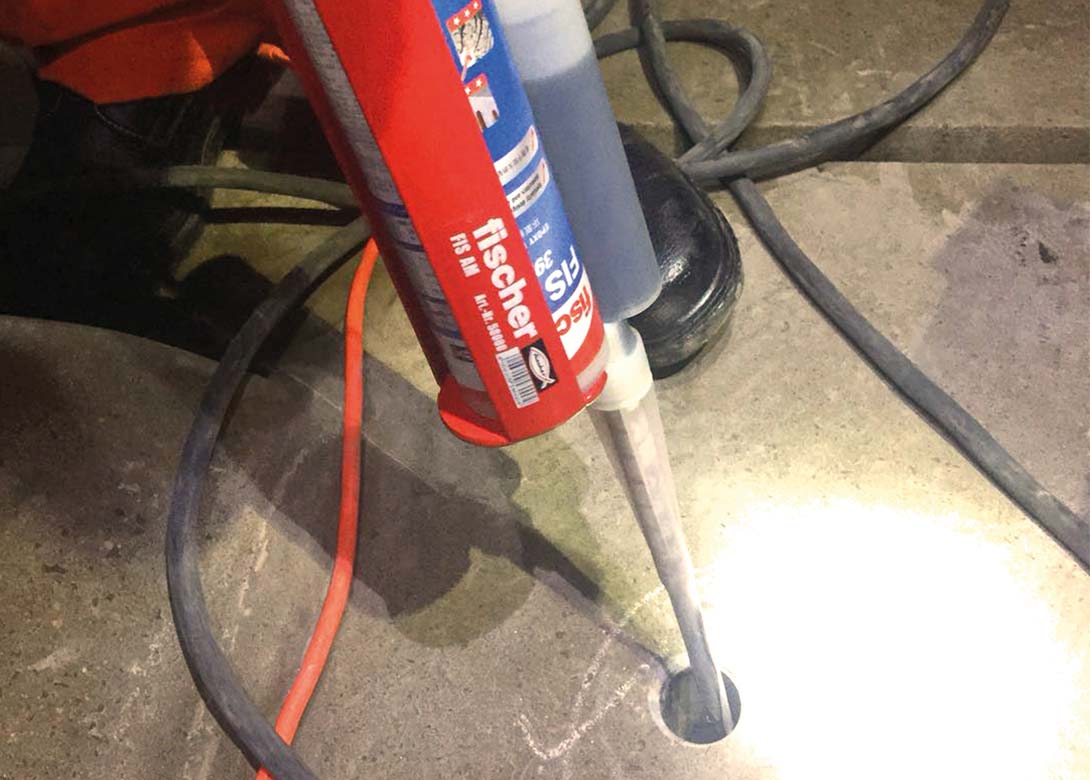

Eight high-speed rail networks, which connect the north, south, east, and west, have been operated for several years. These tracks are currently in a state that requires maintenance and repair. The fischer epoxy mortar FIS EM 390 S is used for the preventative reinforcement of carriageway slabs, as well as for the foundations of track switch and base plates. The work affects the main routes of the railway network including high-speed tracks between Shanghai and Hangzhou, Nanjing and Hangzhou, Beijing and Shanghai, Hangzhou and Ningbo, and Hangzhou and Changsha.

The project is led by the China Railway Shanghai Bureau. “Those responsible are placing extremely strict requirements on the performance of products in order to ensure the effectiveness of anchoring components, even in the event of cracks in the carriageway slabs or base plates. Our FIS EM 390 S meets these high demands with its various properties, such as its strong retaining forces and its resistance to water, heat and humidity – whether in frosty or warm temperatures,” comments Jiang Zong, managing director at fischer China.

This is of high importance due to the sub-zero temperatures that prevail in the north and in the north-eastern provinces of China, and the extremely hot and humid climate experienced in the south and in the eastern regions on the coast. This must be taken into consideration during the planning, maintenance and inspection of both infrastructure and vehicles.

The fischer injection mortar FIS EM 390 S reaches particularly high load capacities in concrete and can withstand extreme conditions, such as the case in China. It is processed with reinforced bars and suitable system components, such as the fischer threaded rod FIS A or the fischer internal threaded anchor RG M I. The epoxy mortar can also be used in water-filled drill holes and in seismic areas. In addition, it has a very high level of resistance to corrosion and fire.

“Overall, it is a safe choice for the maintenance of tracks in China, but also, for example, for the fixing of new tracks or for underwater assembly.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.