The demand to provide efficient and effective bonding solutions in the automotive industry is increasing rapidly, with more focus on resilience, chemical resistance and high-level bonding solutions.

As the industry continues to look for new ways to decrease displacement while maintaining power output, the need for alternatives to mechanical and glue bonding methods continues to grow.

tesa’s reactive HAF thermosetting adhesive tapes are a proven solution to the industry’s greatest bonding challenges. With its resilience, chemical resistance, and high bonding strength, tesa HAF® has been especially designed for situations where new designs and ideas are creating compact lightweight designs that reduce emissions and fuel consumption. When combined with advanced materials such as aluminium and carbon composites, tesa HAF offers automotive OEMs a unique set of synergies to help them pursue greater levels of fuel efficiency and customer satisfaction.

The proven benefits of tesa HAF®

Until now, metal replacement in vehicles has typically focused on lower-load parts, but in order to incorporate these new lightweight materials into higher-load, harsher environment applications, manufacturers need a more reliable and rugged method of structural bonding.

With an adhesive layer that contains nitrile rubber and a phenolic resin, tesa reactive HAF solutions function as thermosetting adhesive tape. When heated, a chemical reaction is started that creates a securely bonded system. Once fully cured, the heat activated film adhesive does not revert to its original state when reheated.

This also offers high chemical resistance to engine oil and solvents and a high cohesiveness at frictional heat (up to 350°C). tesa HAF bonds very well to steel and carbon fibre, which makes it an excellent solution for bonding carbon fibre linings to synchroniser rings, but the potential of this next generation bonding solution is not limited to a vehicle’s transmission. Other proven applications include bonding carbon fibre to clutch discs, mounting sensor plates for gear control, and brake shims to brake pads.

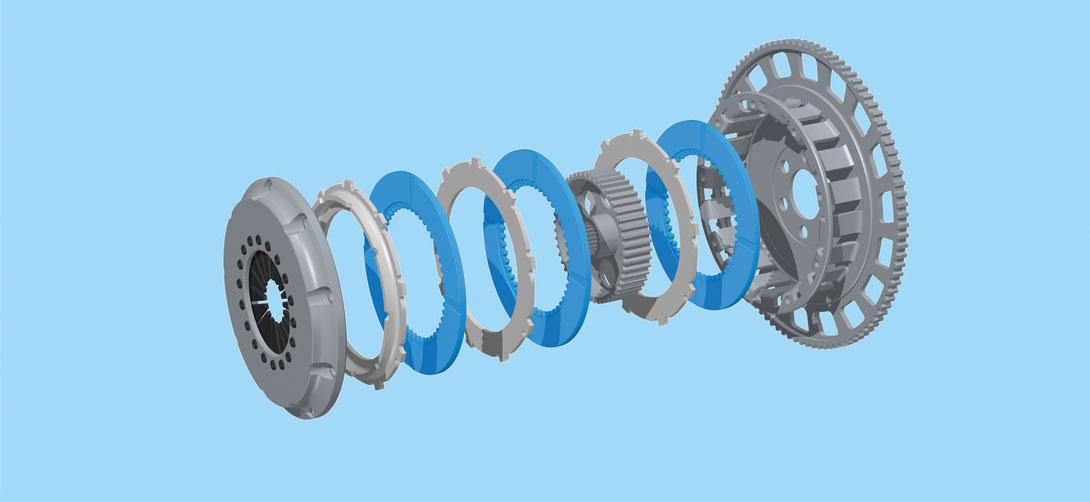

Bonding of friction materials in clutches and transmissions

Where temperature variation, steady mechanical load, and chemicals, cause high stress, a reliable bond is needed. tesa HAF provides bonding strengths comparable to liquid high performance adhesives and is five times stronger than conventional double-sided adhesive tape solutions. It also offers very good resistance to chemicals, oils and high temperatures, with a sealing function to prevent contamination by dust and humidity.

Bonding magnets to rotors

In electric motors, where changing loads apply, permanent magnets are often used to create a magnetic field. tesa HAF provides long-term stability at high load, high chemical and heat resistance, with a constant and even adhesive layer providing stability on small bonding surfaces.

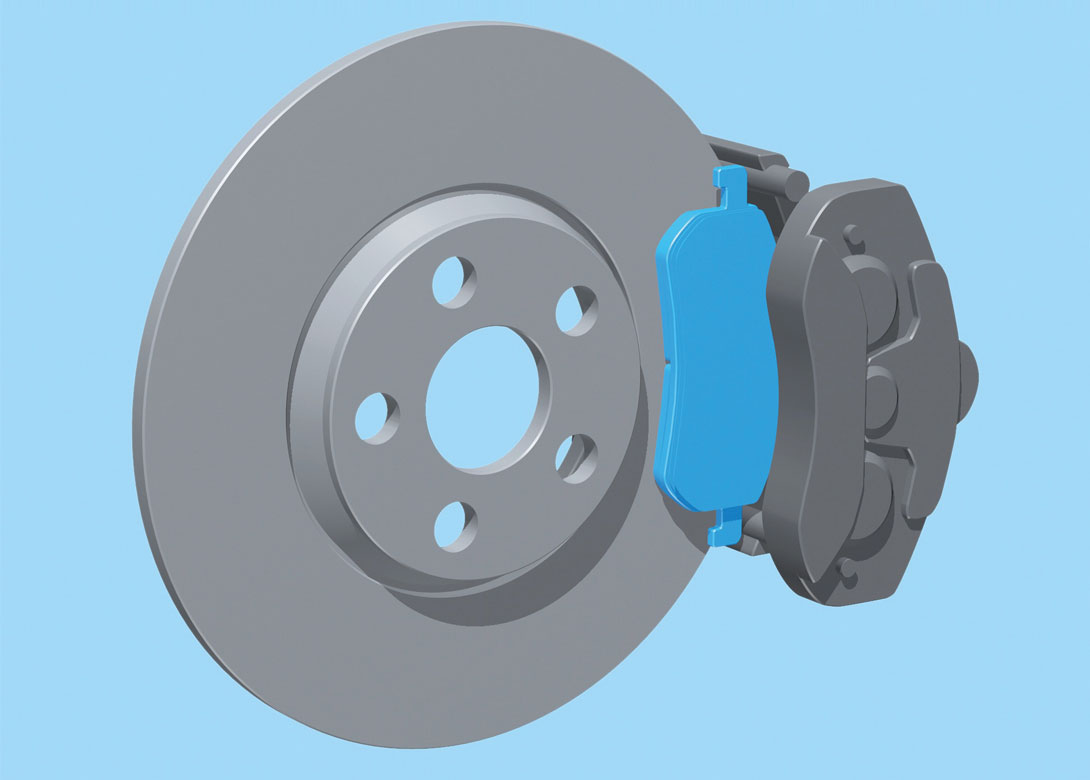

Bonding of brake shims for disc brakes

tesa HAF is used to reduce noise from the braking process by bonding brake shims to the brake pad backing plate. Offering high temperature resistance, good damping properties and long-term stability at high load, tesa HAF boasts excellent adhesion to rubber, metal and coated backing plates and is suitable for die-cutting.

Bonding of fabrics with LTR HAF

Heat Activated Films (HAF) are used in the bonding of materials such as leather and fabrics to dashboards to reduce the effect of Volatile Organic Compounds (VOC) in car interiors. With low VOC and good adhesion to fabrics and heat sensitive materials, tesa HAF provides a flexible feel after application and a short curing time.

With products that offer all the elements required by OEMs to keep pace with high-speed automotive innovations, tesa is well placed to provide its customers with a full range of services. This includes product consultation,

on-site support by a team of technical experts and customer specific analyses and assessments under laboratory conditions at the company’s state of the art Application Solution Centre in Hamburg, Germany.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.