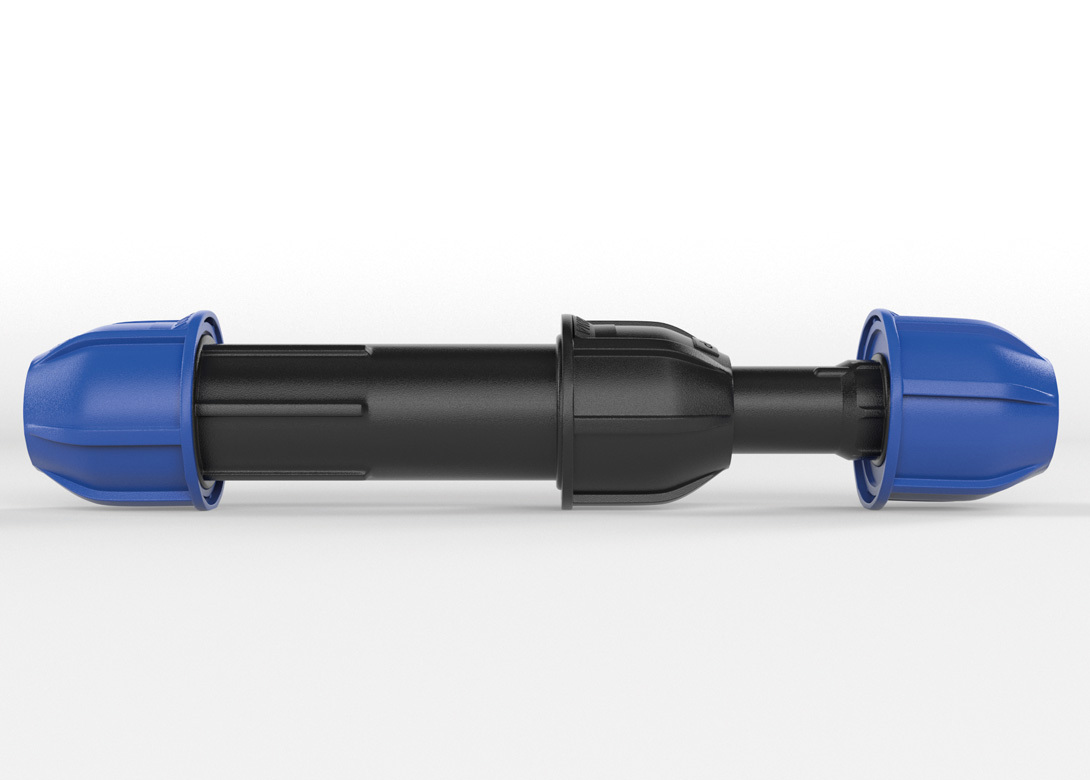

NORMA Group has introduced a new range of Telescopic Compression Fittings that is says is an innovative solution that can help users speed up the process of repairing a broken pipe – compared to traditional pipe repairing methods.

Any fluid transport system is only as good as its connecting parts – with a leaking pipe having the potential to cause massive damage that could become costly and time consuming. With the innovative NORMA Telescopic Compression Fittings, users need less effort and time, as well as less material to fix a broken pipe. It is also no longer necessary to create enough distance between two joiners to flex a new pipe in. The user simply removes the broken section and installs the NORMA Telescopic Compression Fitting by connecting one end to the pipe and extending the other so it fits to the other pipe end.

NORMA Telescopic Compression Fittings are made of polypropylene with telescopic function for the repair or replacement of high and low density polyethylene tubing, from diameters 25mm to 50mm with a maximum service pressure of PN 12.5.

The NORMA Telescopic Compression Fittings are UV stabilised to ensure they will continue to perform, even in harsh sunlight conditions and are the ideal connection for repairing and tapping into metric PE pipe. These ends are also interchangeable with the NORMA PN10 Compression Fittings.

“Rapid installation, durable UV resistant materials, and tight no-loss seals, distinguish NORMA products for sustainable installations in industrial and agricultural or landscaping applications,” states NORMA Group. “Users need to note that this does not include hot water applications. The NORMA Telescopic Fittings are also not certified as compliant with international sanitary regulations for transport of potable water or liquid foods.”

Hall: 1 Stand: 712

Hall: 1 Stand: 712

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.