The desire for support and service has always been part of the DNA of J. LANFRANCO & Cie, which is why the French manufacturer has recently added even more capabilities and equipment to its quality department.

Through the investment J. LANFRANCO believes it has become one of the French flagships when it comes to self-locking safety systems – with the company complying to standards NF EN ISO 898-2, NF EN ISO 3506-2, NF EN ISO 2320 and NF E25-035-2. “Thanks to the investments in our capabilities, and further equipment, our company is able to reach the same level of quality expertise as private laboratories,” highlights J. LANFRANCO. “It guarantees our safety fasteners are designed to meet the highest standards in the railway, mining, nuclear, aeronautical and petrochemical sectors.”

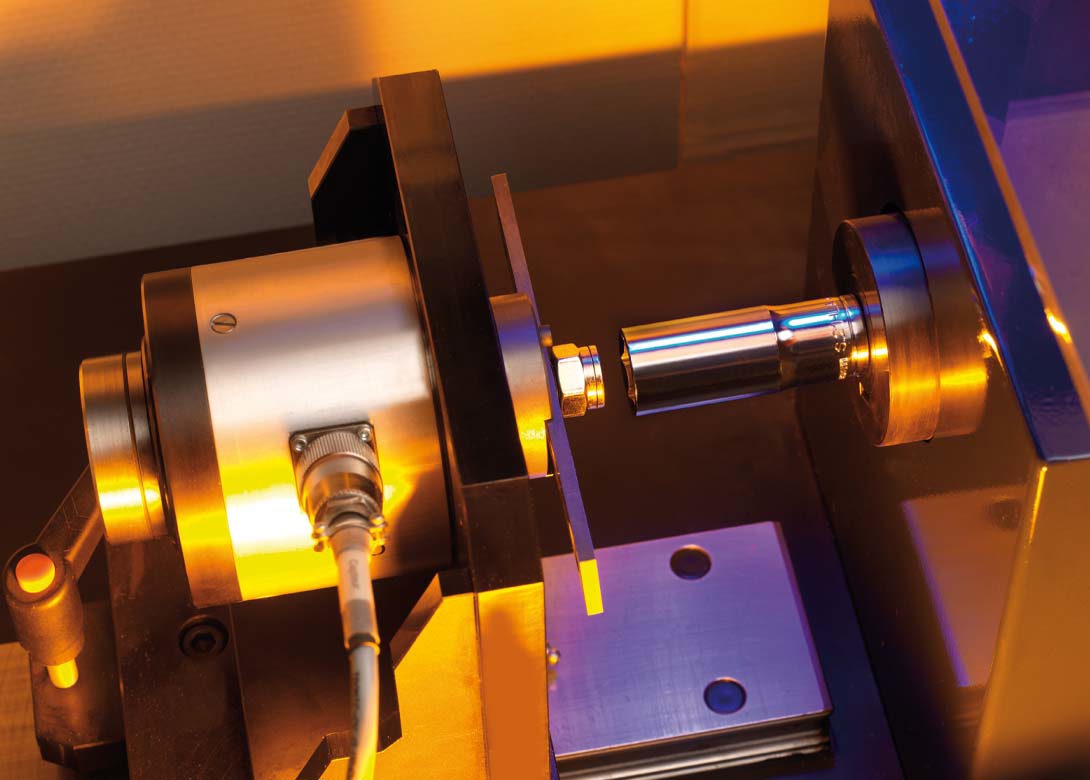

One of the machines that the French company has invested in includes the AUTOMATICA, a new measuring bench that can perform torque/tension tests from M5 to M39 according to quality classes. “We have a new four-way sensor to measure the underhead and in thread coefficient for dimensions ranging from M16 to M39,” points out J. LANFRANCO. “We also carry out tests on imperial dimensions. With the level of precision of this bench, we can accurately measure the performance of the surface treatments and/or Filmogéne offered by our company. This acquisition ensures that our customers comply with the friction coefficients specified in the order, which is vital as this is directly related to the torque and tension in the assembly.”

Another investment by J. LANFRANCO includes the ZEISS binocular machine, which includes a magnification capacity of x 1,000 and the integration of measuring software, which enables the company to directly control the protection thicknesses of its products. “This is a destructive test and enables us to ensure that our products comply with the strictest constraints. The measurement of the minimum thickness on the workpiece ensures a good salt spray (red rust resistance) holding of our products,” reports J. LANFRANCO.

The company concludes: “These acquisitions have enabled us to strengthen our expertise as a manufacturer of safety fasteners. Through these investments, and our involvement in the development of new international standards, our company demonstrates its commitment to remain at the forefront of innovation and to be a major player in the global safety fasteners industry.”

www.lanfranco.fr/en/home-2

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.