Constantly investing in growth is something all companies look to achieve, but few manage it as successfully as Ambrovit SpA – with the Italian enterprise committed to the endless evolution of its product ranges, target markets, and logistics, whilst always focusing on customers’ requirements.

Ambrovit has continued its technical development as a business with the introduction of automated storage for incoming goods. This enables arriving pallets to be quickly added to the system and automatically transported to the automated high bay warehouse – resulting in the flow of products becoming even faster and more efficient.

“It is important as a business you are able to be flexible, so it is easier to follow the needs of the market and customers,” comments Ambrovit. “After doubling the size of the automated warehouse in 2016 to 44,000 pallets – and with the installation of 8 Mlog trasloelevators, plus a 2,000 pallet mini-load system – we are able to process 5,000 order lines per day and ship within 24/48 hours. However, we soon realised that whilst we could quickly and efficiently send out orders, there was a bottleneck at incoming goods and getting the pallets into the system. That is why we decided to invest and automate incoming goods, so we could streamline the overall process.”

Supplying reliability

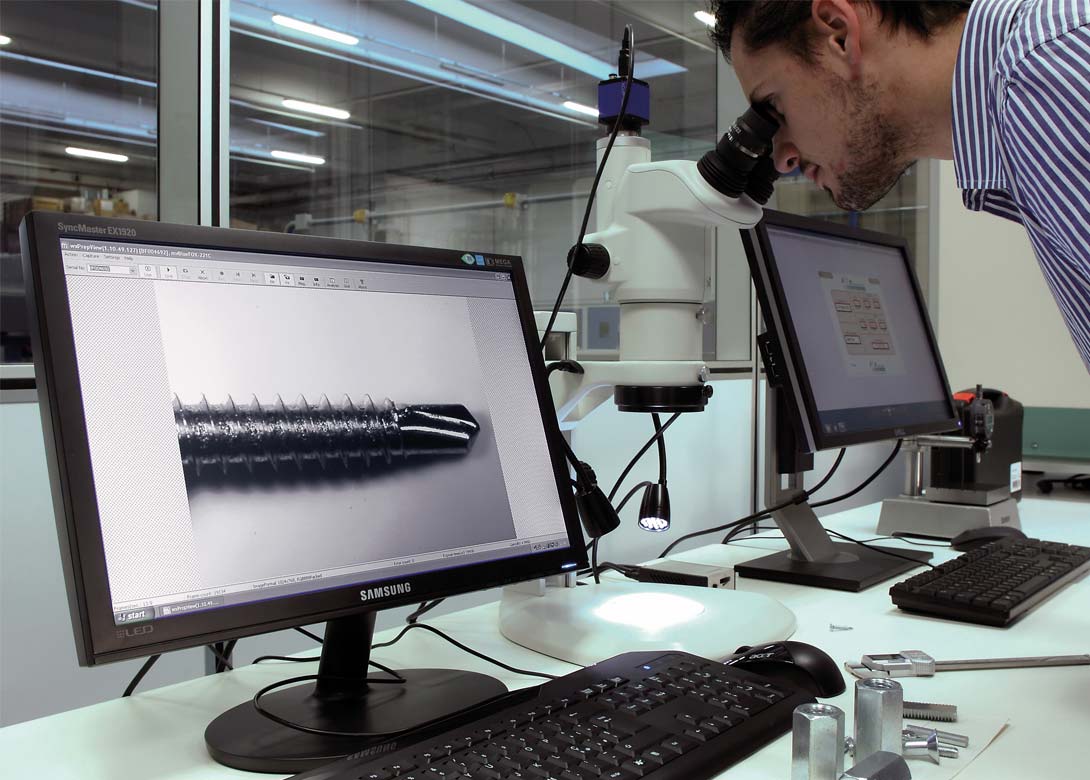

Ambrovit has grown its product range based on the experience within the company, and now offers a catalogue containing a range of over 12,000 products including hex lag screws, drywall screws, carpentry screws, chipboard screws, self-drilling screws, concrete screws, as well as a wide range of nuts, washers and bolts. They are available in various sizes ranging from 2mm to 30mm in diameter and 4mm to 600mm in length. The products are also available in different finishes and galvanic treatments and have CE Marking, with Ambrovit investing in further certifications to guarantee good quality products.

“The number of different products we are able to offer for immediate

dispatch places us amongst the top suppliers within Europe,” states Ambrovit. “We look to keep our catalogue constantly updated with new products, and we will introduce a new version in the first quarter of 2019.”

Guaranteed quality

Ambrovit is always looking to innovate, which it does by using the experience and knowledge within its R&D department to create new products for specific applications, as well as by anticipating the requirements of various sectors.

An example is the company being awarded a European Technical Assessment for its AMBFAST Europe Screws (ETA – 16/0381). “We are particularly proud of receiving the ETA as it is a ‘specification’ more than a ‘certification’, and it is a positive technical evaluation of the quality of our products,” mentions Ambrovit. “An important factor in all the products that we supply is that they are of the very highest quality, which the ETA underlines.”

To ensure this high-quality, the company has an in-house testing laboratory, which is equipped with the latest generation quality control instruments. The company is also certified for its quality management system – conforming with UNI EN ISO 9001:2008. Plus, periodic surveillance audits, carried out by TÜV on all manufacturing processes, also guarantee conformity to all of the requisites laid down by international directives.

As part of the quality control procedure that applies to incoming products, Ambrovit also carries out various tests in its laboratory in collaboration with the University of Trento. For the Russian market, Ambrovit also possesses GOST-R conformity certification, which testifies to conformity, safety, and other essential requirements.

Bespoke packaging

For Ambrovit, packaging also plays a fundamental role. The packing of pieces into boxes is carried out in-house to also guarantee quality standards in this area. All products in the catalogue are packed in micro-corrugated cardboard boxes printed with labels to identify their contents, in conformity with the standards laid down by regulatory norms in force.

Alternatively, they are bulk delivered in bigger 20kg cardboard boxes, in polypropylene bags or in recyclable plastic bags up to a maximum of 1kg. Here too, there is no lack of innovation – with a personalised service enabling customised labels with logos, graphical designs and descriptions to customers’ specifications.

Targeting the future

Ambrovit’s plan for the future is to continue on its path of growth, focusing on the constant improvement of its structures, strategies and products. “We consider that the greatest challenge we will face in the future is to be increasingly reliable and available to our customers,” states Ambrovit. “We are very satisfied with the current situation, but we will continue to work to find every new opportunity for improvement.”

Thanks to its commercial network of distributors and agents, working in a variety of countries, Ambrovit has been able to establish a presence throughout Europe, including eastern Europe, and it is continuing to evaluate the new markets that show interest in the company and its products. Its network of efficient international shippers also means that the company can cover outside of Europe, with each shipment monitored from dispatch to delivery, ensuring that products reach customers on time.

“All the markets are evolving, demanding quality, high performance products that are ever more helpful in the multiple phases of work in all the sectors of use,” points out the company. “It is important that whilst you are constantly aiming at the future, you are also aware that we are currently living through times of rapid change and ensuring you are delivering the products and service customers need.”

It is thanks to this foresight, as well as its vast experience of guaranteeing customers an immediate supply of more than 12,000 items – delivered at the times specified and at competitive prices, that Ambrovit has been able to establish itself as a trusted supplier within the fastener and fixing market and will continue to look to become a byword for fastening systems for years to come.”

Find Ambrovit at Fastener Fair Italy on Stand 620.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.