Founded in 1921, Robert GRASS GmbH & Co KG – a German producer of special nuts in big dimensions and almost all types of turning parts – has recently gone through a significant period of investment and development, after being acquired at the beginning of 2017.

Previously a third-generation family business, GRASS was acquired by Christoph Schulte – an experienced fastener professional with over 15 years industry knowledge – as there was no next generation of the family to carry on the business. “It was a big decision to acquire the company, but I could see GRASS was a great opportunity. It has always had a good reputation for service and the quality of its products, but it wasn’t really growing. I could see potential to develop and flourish and after speaking with Mr Grass I knew it was the right decision.”

To meet Christoph’s plans for the future, it was necessary to introduce a completely new business structure. Robert Grass GmbH & Co KG now consists of two business units: Grass Befestigungstechnik (fasteners) and Grass Stahlservice (a steel service supplying hot and cold rolled flat steel material to industrial customers – with steel expert Micha Franke recently added to the team in October).

“Firstly, I installed a new competence team for Befestigungstechnik’s management including Michael Petereit, production manager, Dieter Beine, technical project manager, and Marius Menze, sales manager,” mentions Christoph. “We then started brainstorming on a new strategy for GRASS Befestigungstechnik and focused on what our product range will be for the future.”

The final decision was to continue to focus on the nut business, but extend the range and the type of nuts available for special industries. “We decided we did not want to try and be a big nut manufacture with large quantities. Instead, we would focus on producing quality nuts for niche areas and work closely with our customers. This includes small quantity nuts made from bars, as well as medium sized quantity nuts made from blanks, which get mechanical treatment.”

Christoph continues: “On the one hand our customers are B2B end users, such as crane manufacturers with the highest quality requirements, as well as the steel construction, wind power, agriculture, power station building and machinery sectors. On the other hand we also work with more and more wholesalers for fasteners with established Kanban supply systems. We want to be a more efficient business, which is more active in the market. That is why we also decided to increase the production for special machined parts that can be turned, milled or drilled, which the company already had a lot of experience in providing.”

In addition to a wider nut range and special machined parts, GRASS will continue to produce other niche products such as the swivel for the hooks on cranes (1 tonne up to 40 tonne load capacity), which it has been producing since 1975. Also, the business will look to globally source special fasteners for customers – such as special cold formed nuts, stainless steel washers, etc. “This means anything GRASS cannot produce internally, it can still provide a solution to customers,” adds Christoph.

Once the new management team had decided on a strategy and product range, it needed to focus on the production floor. “There was a lot we had to do on the production side,” explains Christoph. “We had to restructure the production process completely. Previously the machines were split between two halls, and old conventional machines were still producing good products, which was simply not cost-effective.”

New CNC turning and milling machines have been introduced, which guarantee the same quality products are produced but more efficiently and effectively. “We have kept a couple of the old conventional machines to work on any small batch orders requested by customers,” says Christoph. “However, the majority of products will be produced on the new equipment.”

The new production layout into one hall has enabled GRASS to improve the production flow throughout the entire process. The other halls have also been reorganised so that one is focused on solely logistics and stock, and the other is for re-working such as washing, grinding, marking and testing parts. “It is a lot more structured now,” mentions Christoph. “We have created one fluent optimised line throughout production from start to end. Plus, whilst introducing the new machines and changes, we have still been producing products and serving customers to the high service levels they are accustomed.”

In addition to the production floor, the offices have also been refurbished. “The offices were previously three separate rooms,” mentions Christoph. “We decided to knock down the walls and create two larger rooms, which would bring the office team together and make it easier to work. We have also introduced a completely new network and software system. We have even improved the outside of the premises, including re-laying the tarmac in the car park and painting the exterior of the building, as well as adding a new sign.”

Just as important as re-structuring the physical aspect of the business was making certain that the employees were kept up to date on the change of the business strategy. “It was crucial for us to discuss why we are making the changes with the employees and how they will benefit the company. It is not easy to change a business strategy, it takes time. You also need to make sure the customers understand what the new strategy is going forward and how they will benefit. A big help was the previous owner stayed with us until the end of September 2017, as part of the changeover process, as a consultant. He offered a lot of advice and know-how regarding the products, customers, machinery and employees. Our employees can see the re-development, they can see the machines and they are excited about the future. They know we are all in this together and every employee is vital in the business.”

GRASS 2.0

With the internal structure of GRASS updated, the next step was to look at new business opportunities. “The company was reactive rather than proactive,” explains Christoph. “It has been sleeping and we are looking to wake it up and raise the profile by entering new markets. Previously GRASS was focused on predominately the Germany market, but we are now looking to branch out into other markets across Europe.”

Christoph continues: “There are a lot of suppliers in the market, so you need to earn the trust of the customers and ensure you offering the right price and the right package – whilst continuing to offer good quality products. That is why we offer a personal service and work with customers on drawings and technical support to help improve products. We want to be a reliable partner that can be flexible and react quickly to the needs of the customers. The experience and quality GRASS has gathered over the past 90+ years, plus the new structure and management team, enables us to be the right partner for customers in the future.”

GRASS products

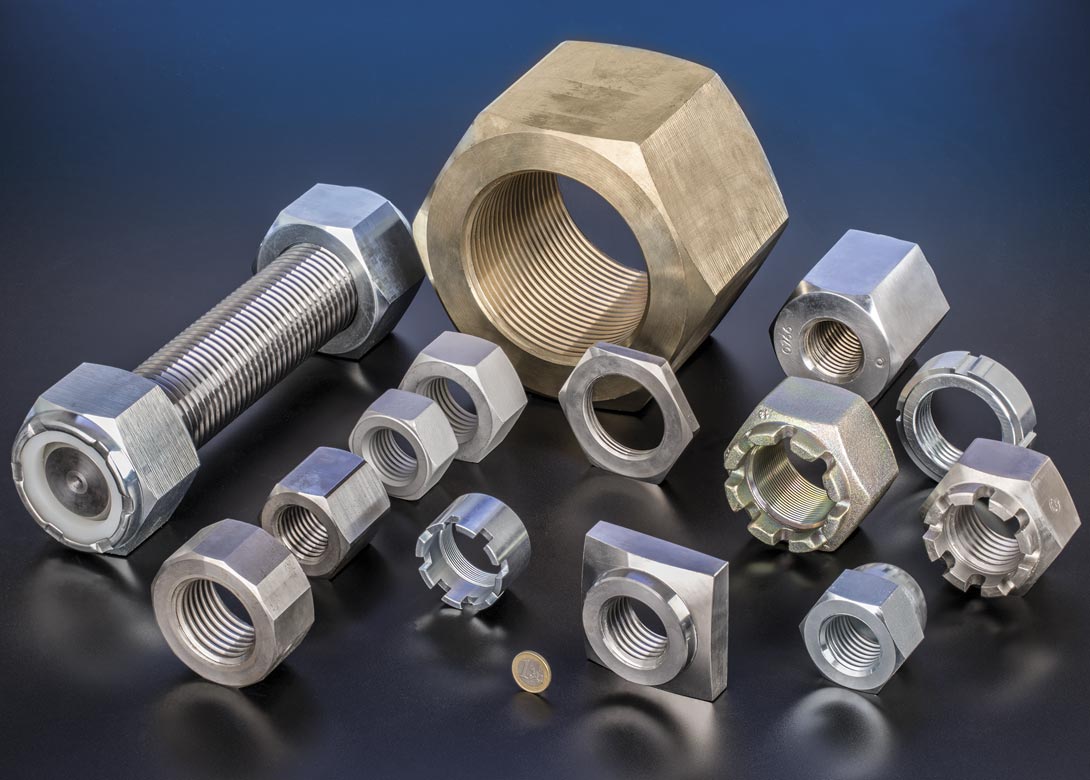

GRASS produces special and standard nuts with the highest levels of precision in round, square-head, hexagon and octagon dimension range M24 – M150. The company is DIN EN ISO 9001:2008 certified.

According to customer preference, the nuts can be individually annealed and surface coated. All products are identified with the RG manufacturing marking, along with the hardness class and traceability number.

Materials available include ASTM A 193/194, free cutting steels, hardened and tempered steels in accordance to C45R, 42CrMo4+QT, 34CRNiMo6 – 30CNiMo8, temperature resistant, heat and ageing resistant steels, rust and acid resistant steels, brass and bronze, etc.

Turning, milling and processing

The portfolio also includes the turning of steel parts with diameter up to 4mm to 800mm from bar and chuck rotation parts with 350mm and 650mm lengths.

Materials available include free-cutting steel, structural steel, alloy steel, case-hardened, as well as annealed steels, brass, copper and aluminium.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.