ME-RIPP showcases Adolf Menschel’s capabilities

30 November 2015

For more than 100 years Adolf Menschel Verbindungstechnik GmbH & Co KG – a business unit of Würth Group – has produced high-quality fasteners on state of the art machinery at its site in Plettenberg, Germany.

The Menschel product range comprises of more than 50,000 different kinds of fasteners – the majority special parts made to drawings. “We specialise in self-cutting and self-tapping screws but we can produce a wide variety of products,” explains Stephan Wennrich, sales management at Adolf Menschel. “Even products with a complicated geometry are no problem for us, and we can produce smaller quantities starting from 20,000 pieces.”

Menschel’s production range includes self-tapping screws, grooved screws, screw and washer assemblies, self-locking screws, as well as cap screws. All these screws can be purchased with different finishes – galvanised, organically coated and, if required, with microencapsulated locking compounds. Head styles include pan head, countersunk head, raised countersunk head, cheese head or mushroom head, as well as hexagon, also with a collar. Customers can choose between hexagon recess or cross recess Phillips, POZIDRIV® or MESTERN. Furthermore, Menschel can also supply special and cold formed parts made of steel and stainless steel according to standards, drawings or samples.

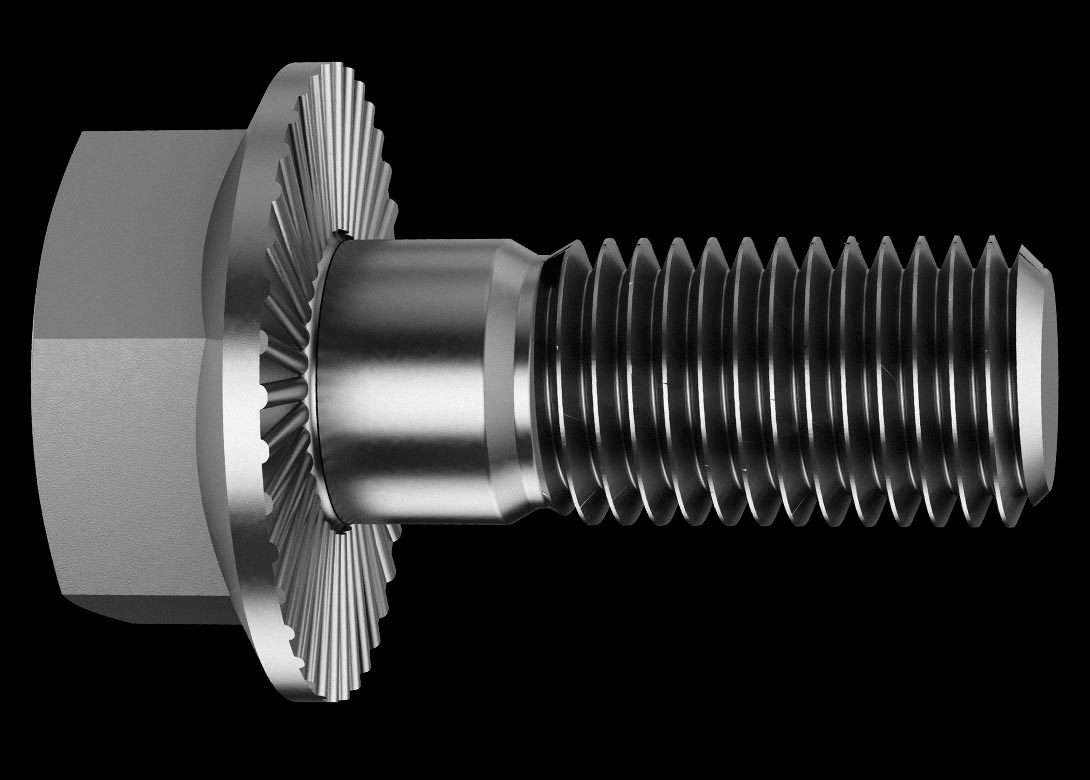

A leading product for Menschel is the ME-RIPP – a self-locking screw that is available from M5 – M20 and has received Deutsch Bahn approval under DIN 25201/BN 205 03i-01. During installation there is no chip formation and special ribs under the head of the ME-RIPP ensure that there is no damage to the surface of the mating material – which Menschel says helps reduce losses in pre-tensioning force and enables the ME-RIPP to offer a perfect response when tightened.

“The ME-RIPP screw can be used in a wide variety of industries including commercial vehicles and agricultural machinery,” explains Stephan. “Thanks to the know-how of our staff, and 100 years’ experience, we are able to reliably provide the ME-RIPP to customers – guaranteeing them a high-quality product that provides a high-level of safety.”

Menschel’s ability to consistently produce high-quality products is thanks to its state of the art production department, which includes the latest technology in multi-stage presses. The company recently added two new five stage cold form presses that enable it to produce all current head shapes and drive systems up to 12mm diameter and 90mm length. Menschel also has another five stage press, which is equally state of the art and enables it to produce all current heads and drive systems up to 22mm diameter, 120mm long.

“A key part of our success is our vast manufacturing capabilities, as well as the close relationships we have with our customers,” points out Stephan. “We build strong partnerships with our customers and look to work with them to put their ideas into practice. We offer a complete service package where we visit customers’ facilities and identify their fastening requirements. We can then advise, consult and design the perfect fastener solution that will meet the customers’ needs.”

Menschel’s high-quality special products are required by the automotive industry – where it is an approved OEM supplier, the optical and electrical engineering industry, electrical industry, as well as plant and machine engineering sectors. The company is accredited to ISO/TS 16949, ISO 9001 and ISO 14001.

“We are very proud of our capabilities and the high-quality of our products we can supply customers around the world,” says Stephan. “For us ‘Made in Germany’ is not just a statement of where the product was produced. It is a seal of approval for our consumers and business customers and stands for sustained good quality, safety and a high technical standard.”