By Bernd Schreiber, Willem Romanus, and Yong Lee, at Arthur D. Little

With the advent of digital, many organisations are looking to move away from Lean management in search of more radical performance gains. This article explains why Lean principles are still vital, and how integrating them into digital transformation can be a highly effective way of simplifying the process. This allows companies to identify and apply the most effective levers for the digital journey.

The phrase “We’re through with Lean – it’s time to go digital,” will sound familiar to the ears of many executives today. At first sight the idea of abandoning Lean and trying something ‘new’ that delivers more radical improvements seems appealing. However, although Lean and digital initially appear largely unrelated, ignoring Lean principles may be risky, and can even prevent digital transformation projects from being successful.

Successful companies have achieved outstanding performance by incorporating Lean management at the centre of their corporate transformation. However, even in those companies for which Lean once transformed ways of working, the limits of what can be achieved have almost been reached. Numerous companies suffer from Lean ‘fatigue’, with managers frustrated with results that are increasingly incremental.

The shift to digital

At the same time the potential of digital technologies to transform performance is now widely recognised. However, most companies struggle to find the right approach to effectively grasp the benefits of this digital promise. Indeed, choosing from the plethora of new options provided by digital technologies is a real challenge. Typically, it is unclear where to start and how to prioritise a company’s efforts and resources to drive tangible results. While some companies have been able to achieve a radical performance increase of up to 50% or more, many have become stuck in a situation in which initiatives happen in silos, efforts lack coordination, and successes are limited or even non-existent.

Recent experience has shown that integrating Lean principles into digital transformation can be a highly effective way of achieving radical simplification of the process, allowing companies to identify and apply the most effective levers for the digital journey.

Traditional Lean excellence

Companies that rely on Lean principles achieve relatively high performance levels compared to their competitors.

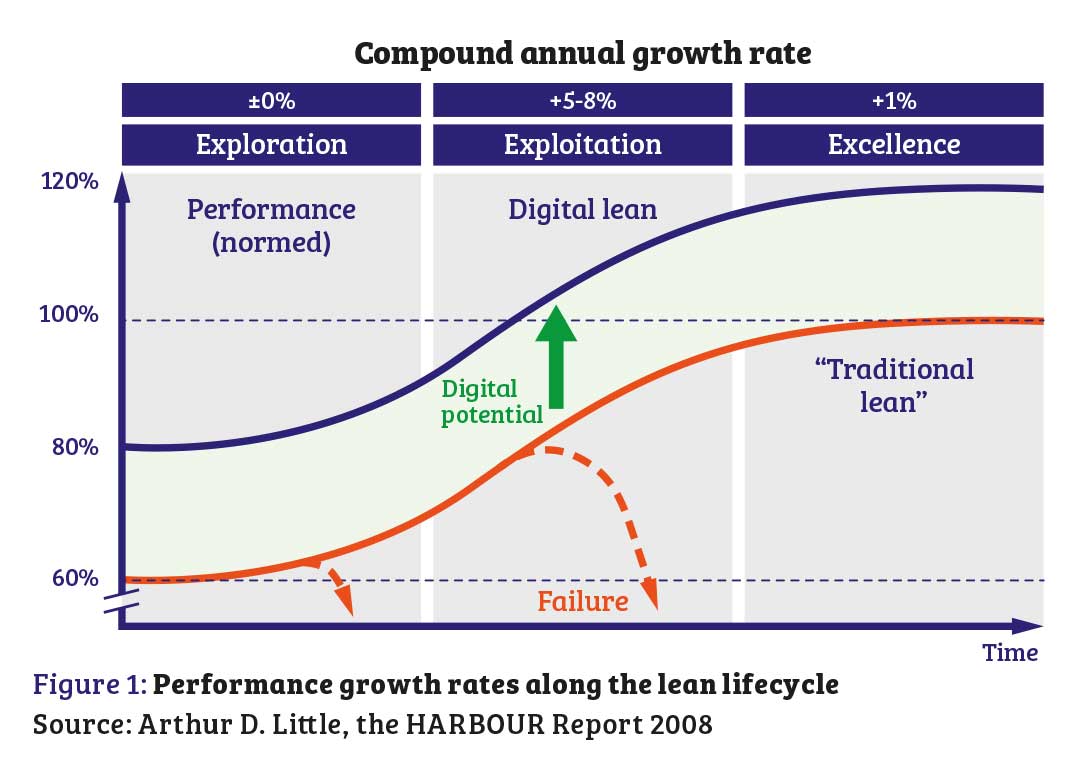

A recent Arthur D. Little automotive study classified the Lean lifecycle into three phases and determined annual company growth rates in each phase. Using a key automotive productivity indicator (hours per vehicle) as a measure, the correlation with Lean implementation was analysed (see Figure 1).

Performance growth of up to 8% is common during the Lean Exploitation phase. This decreases as performance improves and tends to stabilise at around 1% in the Lean Excellence phase. Digital technologies have the potential to make a further step change improvement across all phases. Similar trends have been identified in other industry sectors.

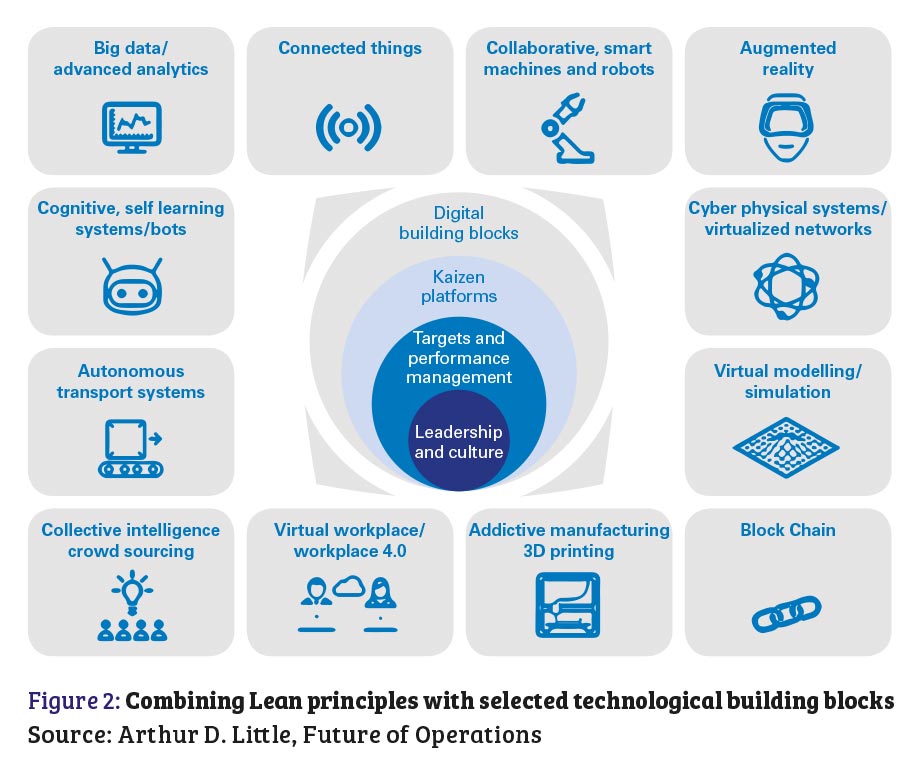

Whatever the industry, outstanding Lean organisations tend to be strong in the three ‘Lean pillars’ – leadership and culture; targets and performance management; and Kaizen platforms.

However, despite the widespread understanding of these principles, many Lean journeys fail. Companies often focus too much on tools rather than philosophy, and on waste removal rather than customer value. Disappointing incremental improvements and Lean ‘fatigue’ are common symptoms of this failure.

Improving performance through new digital technologies

The advent of new digital technologies undoubtedly provides huge opportunities and levers for making a further step change in performance. However, companies that simply introduce new technological devices and systems, without considering the value stream holistically, run the risk of failure. There are several reasons for this:

Selecting the right technology building blocks

Overcoming these challenges requires excellent knowledge of available technologies and a deep understanding of how and where they can affect the value stream – this is where the three Lean pillars are invaluable.

Each company needs to configure its own set of technological blocks, to address its organisational characteristics and priorities. Five categories of technological building blocks are defined in Arthur D. Little’s digitalisation framework: ‘Future of operations’. This classification helps companies to trace operational needs to the relevant building block:

These building blocks are interconnected, and therefore need a holistic and integrated design approach. They apply across the organisation, in both core operational functions such as manufacturing and logistics, and in support functions such as robotics process automation (RPA) in production planning and finance.

By adopting Lean principles, including a classic Lean value stream analysis, it is much easier to identify the right areas and the levers to make the change (Figure 2).

Assessing the digitalisation potential of the value stream

Radical shifts in performance can be achieved by embedding new (proven) technologies in the value stream to overcome factors that have traditionally limited performance. The full digitalisation potential of the value stream may be derived using a design approach based on two key questions:

1) Which physical process steps can be automated by mature and proven technologies?

2) Which remaining non-physical (information) process steps can be radically digitalised?

First, design a Lean value stream on the greenfield. Simplify the value stream radically by eliminating interfaces through consolidation and integration – make the value-add visible. For each process step, especially for the non-value-adding ones (waste), ask why this step needs to be processed by an employee and by what technology it should be automated.

The immediate use of mature technological building blocks on standardised processes will deliver more reliable processes with less failures. Significant increase in productivity is the consequence of shifting the focus from eliminating waste to creating value-add. The greenfield value stream design will differ radically from the current value stream: It reveals its digital potential.

Second, automate and digitalise manual information processing and standard decision making. Strive for a fully automated target condition in which the employee is just monitoring and confirming automated quality gates.

Reduce manual intervention to zero – especially for high frequency routines, in which employees transfer data between programs, or even for very complex decisions, robotics process automation, artificial intelligence or decision supporting systems radically simplify administrative information flows.

Digitalised information flow does not only produce less failures and accelerate workflows significantly, but also creates new value and optimisation opportunities through the digital visibility of big data.

Developing Lean digital capability

The ability to effectively and efficiently digitalise an organisation’s value stream is, unquestionably, a source of future competitive advantage.

Identifying and integrating the most appropriate digital technology into the value stream requires a profound understanding of all related business processes, as well as the technologies on offer and their relative maturity.

As with Lean management, developing the required capability and establishing the required mind set throughout the organisation remain a top management issue. The more employees and managers adopt this new lean digital mind set, the sooner efforts to digitalise will succeed in delivering step changes in business performance.

Insight for the executive

In order to be successful and overcome typical barriers, companies need to ensure that Lean principles are well integrated into their digital transformation efforts. Companies need to:

1. Select the right building blocks based on specific value creation potential. This requires a broad and profound knowledge of state of the art technologies.

2. Use Lean principles to radically simplify the value stream. A digital greenfield design can be used to identify the digital potential in the value stream.

3. Avoid digital shortcuts, as they typically fail or lead to disappointing or unsustainable results.

4. Start developing a Lean digital capability, which will form the basis for a long-term and sustainable competitive advantage. This implies a cultural change in the organisation and requires top management attention.

Completing these four actions will enable companies to achieve radical shifts in performance levels by combining digital and Lean. Returning to the opening statement of this article, the conclusion is simple. It is time to go digital – but this means that Lean principles are more needed than ever before to help transformation efforts succeed over the long-term.

About the authors

Arthur D. Little is a global management consultancy that remains focused on innovation. Bernd Schreiber is a partner in the Frankfurt office of Arthur D. Little and leads the Global Operations Management Practice; Willem Romanus is a principal in the Brussels office of Arthur D. Little and a member of the Global Automotive & Manufacturing Practice; and Yong Lee is a Manager in the Frankfurt office of Arthur D. Little and a member of the Global Operations Management Practice.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.