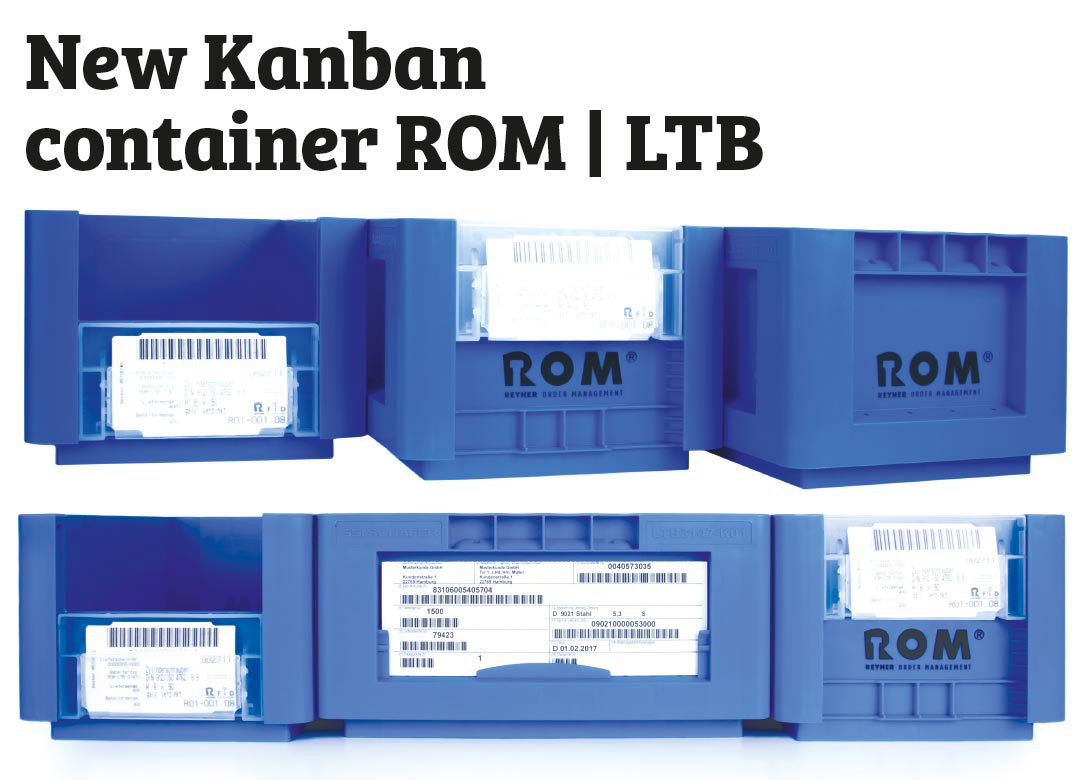

F. REYHER Nchfg GmbH & Co KG has developed a new ROM | LTB container in cooperation with SSI SCHÄFER – a leading provider of systems for intra-company material flows – which it says is a well thought out concept based on practical experience. It can be deployed anywhere in production and logistics where material replenishing is steered by Kanban systems.

The new REYHER container is fitted with an extremely versatile sliding mechanism that can be transformed from an open visible storage container into a transport container in one action. For transporting nuts, screws or other fasteners the sliding mechanism is simply pulled up. No extra load securing plug or flap elements or label holders required. This saves time as well as environmental resources.

When the container is in use, the sliding mechanism is switched into its lower position, creating a generous opening for removing materials from the container. Where space requirement is an important factor, the new ROM | LTB scores with up to 28% higher fill volume compared to conventional containers. This means storage capacity is increased – optimising space used. The REYHER container can also be combined with many common sloped or flat bottom shelving systems and with a depth of 297mm, and a width of 197.5mm, it helps to optimise shelf space. This means that in a standard shelf rack that is 1,000mm wide, five containers can be placed side by side instead of the usual four containers.

Labelling is just as flexible as combining the REYHER containers with various shelving systems. The transparent label holder in the sliding mechanism, on the front of the container, protects the label from soiling or damage and it cannot fall out. The label is not permanently fixed to the container so that it can be easily exchanged. For companies where VDA regulations apply, there is a special label holder available on the side of the container, in-line with VDA standards.

When designing the container various parameters were taken into consideration. When small items are stored in the ROM | LTB the rounded interior bottom makes removing items easier. For heavy items, stability is provided by the strengthening rib-structure on the outer base of the container. Ergonomic aspects are taken care of by the recessed grips on the containers, which have extra robust strengthening. The openings on the top edge of the container are for automatic handling by systems or robots.

The ROM | LTB container also looks good. The subtle shade of blue gives it a friendly hue. In addition, the sliding mechanism closes up completely in every position, which makes for a positive appearance and also provides operational safety, since no small material remainders are left that could disrupt the shelving system.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.