SACMA Group is well known for designing and manufacturing combined headers that are able to produce fasteners from M4 to M24, and to date, has provided more than 4,000 combined headers worldwide. Here, SACMA outlines step-by-step how combined headers work and the benefits of its innovative technology.

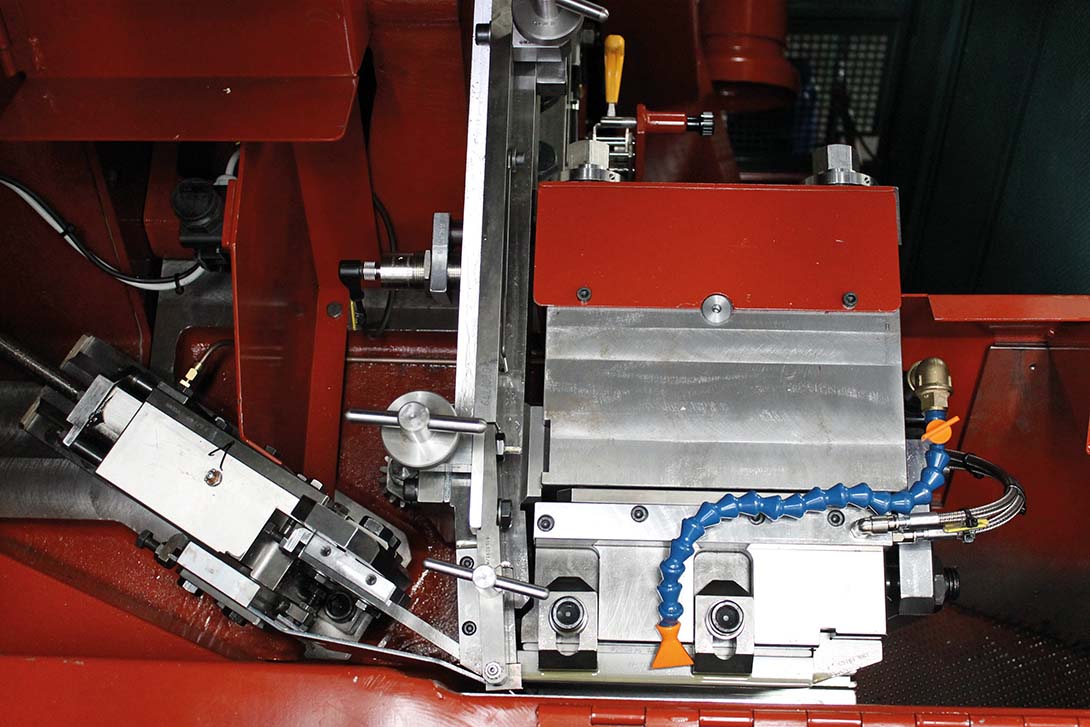

All SACMA machines are fitted as standard with hydraulic clamping of die side adjustments, such as threaded sleeves, kick out levers and trimming cam. The M version, with motorised DKO adjustment, is an important system to reduce the changeover time and to speed up the fine setting. The set-up data of each product code is also stored in the PLC.

Via the control panel, the operator can adjust the machine automatically to the feed length, the stock gage position, and the DKO stroke. As well as this, the hydraulic clamping of adjustments and tools is a great help when setting the machine, assuring the best repeatability.

Via the control panel, the operator can adjust the machine automatically to the feed length, the stock gage position, and the DKO stroke. As well as this, the hydraulic clamping of adjustments and tools is a great help when setting the machine, assuring the best repeatability.

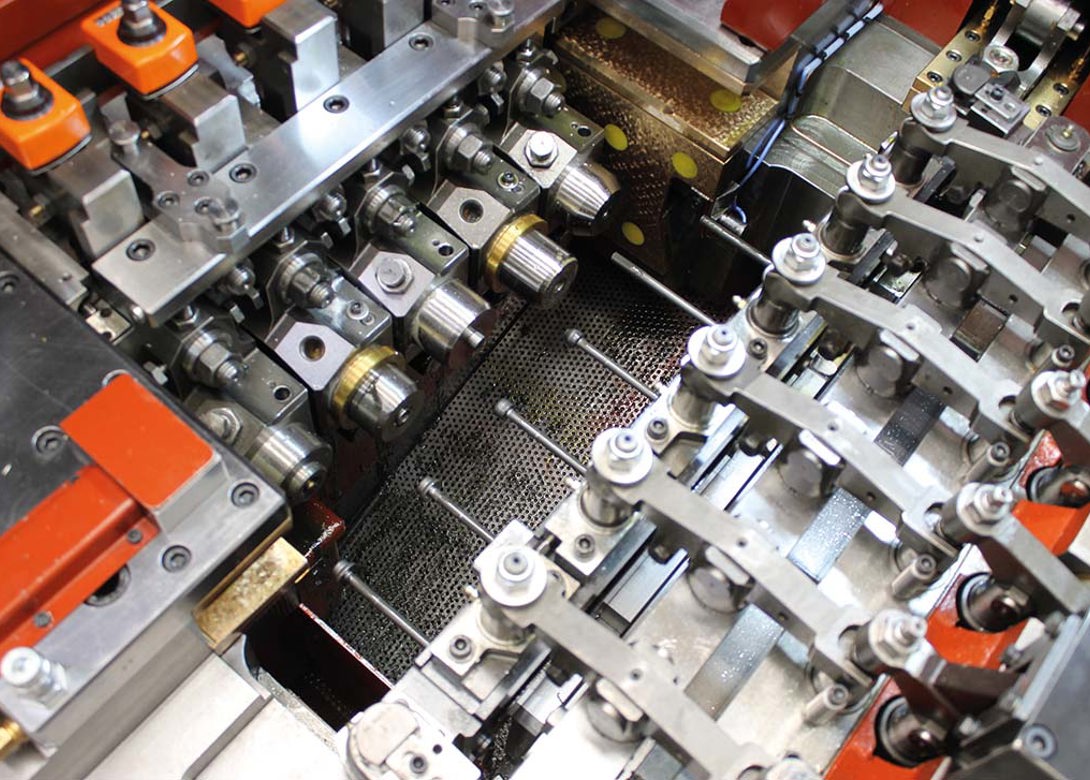

“We are proud that the transfer mechanism of SACMA combined machines is considered the world benchmark,” comments SACMA. “So much so, that the transfer mechanism has been the subject of many unsuccessful imitation attempts.” The precise movement of the transfer fingers is determined by a smooth oscillating mechanism, which is generated by perfect desmodromic cams. This also enables a perfect control of the whole system at the maximal production speed. The multiple adjustments, such as timing of the transfer phase, variation of the clamping force, variation of the opening/closing speed of the fingers, as well as the absence of springs, also allow the safe transfer of long and short parts at the highest speed.

From the forming station the parts are directed to the pointing station by means of a fingers elevator, which is easily adjusted in width according to the diameter of the shank. The adjustment is made by a micrometric system and is simple to implement. The forged parts are then fed to the pointing unit where the extremity of the shank will be machined. Here it is possible to produce points with different geometries and angles, including the typical 90° robot point widely used in the automotive industry. From the pointing station the blanks are then fed to the flat die thread rolling station.

The threading station carries a flat die, alternating motion, main slide. As well as this, a stop gate and a single starter blade system, fitted at the end of the rails, helps guarantee a perfect introduction of the blanks between the roll dies. The match adjustment of the threaded profiles can be obtained either by means of the eccentric mechanism of the connecting rod, which drives the slide, or by means of a wedge that provides vertical adjustment of the fixed die – which can be adjusted in all three directions. Next, calibrated hardened spacers are quickly fit behind the fixed die according to the thread size for a quick changeover.

The threading station carries a flat die, alternating motion, main slide. As well as this, a stop gate and a single starter blade system, fitted at the end of the rails, helps guarantee a perfect introduction of the blanks between the roll dies. The match adjustment of the threaded profiles can be obtained either by means of the eccentric mechanism of the connecting rod, which drives the slide, or by means of a wedge that provides vertical adjustment of the fixed die – which can be adjusted in all three directions. Next, calibrated hardened spacers are quickly fit behind the fixed die according to the thread size for a quick changeover.

In addition, SACMA’s V version of the combined headers has been designed for the production of very short fasteners. A shutter elevator feeds the blanks from the heading station to the bowl of a vibratory feeder, where the parts are correctly orientated and delivered by rails to the pointing unit. The pointed blanks thereafter go to the rolling station to form the thread. By means of dedicated devices, the pointing operation or the rolling operation can be bypassed, according to the process the customer intends to apply.

In addition to the multi station combined headers, SACMA is also reintroducing the 1D2B combined header for small and self-tapping screws – widely used in different industry fields. This combined header can produce fasteners and screws for the automotive, construction, electric/electronic, and white goods industries, starting from wire. By having the forming and thread rolling all in one machine, SACMA says its combined headers are a good solution for high productivity requirements, consolidation of production methods, as well as floor space utilisation and workflow in fastener manufacturing.

“The floor utilised by a combined header against a line of connected machines is normally 1 to 3. Consequently, more parts produced per area make the overall plant more profitable and efficient,” explains SACMA. “Often one operator can manage two or three small combined headers, saving maintenance costs – as well as a faster production changeover thanks to the fully motorised adjustments and the direct drive motor, which enables a very easy set-up of the threading station.”

“The floor utilised by a combined header against a line of connected machines is normally 1 to 3. Consequently, more parts produced per area make the overall plant more profitable and efficient,” explains SACMA. “Often one operator can manage two or three small combined headers, saving maintenance costs – as well as a faster production changeover thanks to the fully motorised adjustments and the direct drive motor, which enables a very easy set-up of the threading station.”

Other advantages of the combined SACMA headers include a soundproof enclosure, as well as a sealed area which houses the cooling and lubricating oils to ensure no oil leakage, less pollution and a clean and safe working place. All SACMA machines are also recognised as ‘quick plug in’ equipment, which means the combined headers are ready for production just a few hours after installation.

For the new SACMA combined header model KSP12-R, these advantages mean it can run fasteners from M3 to M8, with a maximum shaft length of 60mm, in the best technical and economical way. The KSP12-R combines typical SACMA solutions, proven by thousands of machines, with the most advanced mechatronic technology available on the market. The one piece main frame featuring pearlitic cast iron naturally aged for at least 12 months, as well as being machined with high precision, is a guarantee of rigidity and stability for all machine life.

For the new SACMA combined header model KSP12-R, these advantages mean it can run fasteners from M3 to M8, with a maximum shaft length of 60mm, in the best technical and economical way. The KSP12-R combines typical SACMA solutions, proven by thousands of machines, with the most advanced mechatronic technology available on the market. The one piece main frame featuring pearlitic cast iron naturally aged for at least 12 months, as well as being machined with high precision, is a guarantee of rigidity and stability for all machine life.

Main set-up adjustments for the KSP12-R are now also motorised for a quick and friendly changeover. This includes a S-feed wire feeder driven by a torque motor, motorised wire stock gauge and DKO, as well as threading starter driven by torque motor with self-learning function. The quality management is facilitated by two gates interfaced with the load monitoring system and discharging NC parts, after the header and after the roller. An optional sophisticated load control system protects the machine against overloads and monitors the forming and rolling processes. Scraps separating grids in different sizes are available when producing self-tapping screws.

“The benefits of these features make the KSP12-R the best value for the customer, allowing a quick pay back of investment,” concludes SACMA. “The legendary durability of SACMA machines, together with the everlasting availability of spares, is the guarantee of long-term success and profit.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.