The Videx hot forging line consists of six to ten machines, which the company states is the only hot forging line of its kind – replacing the traditional separate forging presses and trimming operation machines, The Videx line is also fully automated.

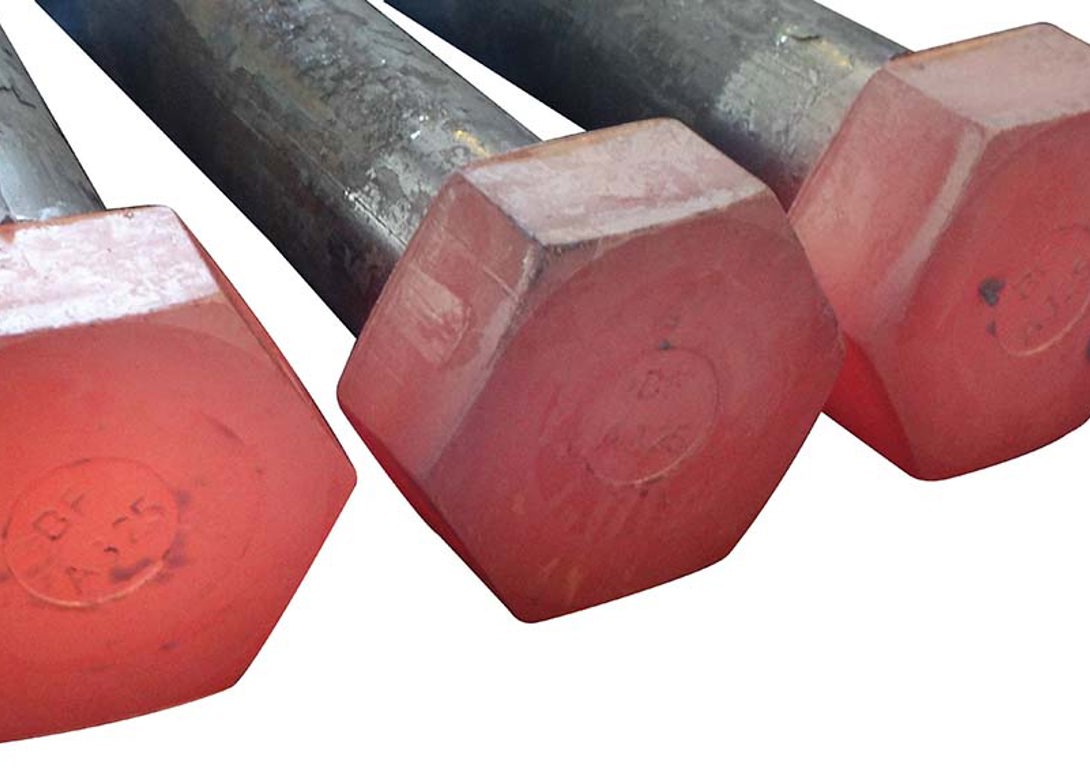

Available in 100MT to 500MT,.the Videx forging machine has a thread range of M20 to M48 and up, with a part length of 200mm – 1,000mm. The production rate is 4 – 6 parts per minute. The line consists of straighten and cut machine for coil or from long bars; a chamfer machine; extrusion machine – extruding the chamfered end from major to pitch diameter; transfer machine – feeding the bars through an induction heating machine; double blow, solid die forging machines with five stations – one feed station, two forging stations and two ejecting stations; cooling conveyor; and a thread rolling machine.

The chamfered and extruded bars are fed into the die by a pneumatic piston. The feed dial then indexes the parts to the first forging station, which upsets the parts and breaks the scale. To complete the head shape, parts are then moved to the second forging station. After heading, the parts are ejected to a conveyor that transfers them onto a cooling conveyor – saving intermediate storage and handling – before the parts are placed into the thread rolling machine.

“The VSD line is a unique solution, starting from the raw material and ending with a fully sellable product,” comments Videx Machine Engineering Ltd. “It is the fastest of its kind and enables the production of long bolts. The machine also has in-line cooling, which saves intermediate storage and handling, and features a single panel control for all machines, meaning only one operator is required to run the whole line.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.