Lazpiur S.A has developed the new BEGItech CLT machine, which is able to verify parts with an output of 800 fasteners per minute – helping to further expand the company’s range of inspection machinery for fastener products.

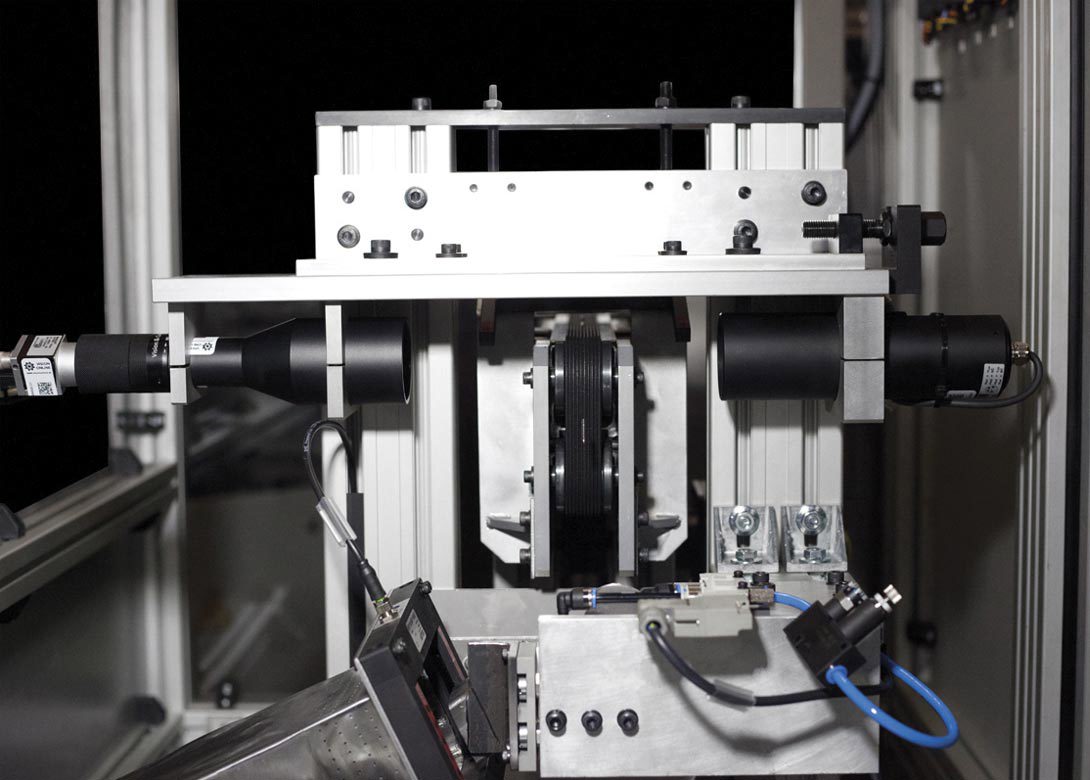

In-line with the company’s policy to build on the latest technology available, the BEGItech product range relies on powerful software with the calculation capacity to verify 800 parts per minute. An innovative feature of the BEGItech CLT machine is that the inspection is performed while the part is in the air. This design removes any interference between the vision system and the measured object – doing away with eventual dirt, wear or glass breakage and other issues affecting the measuring function. The part is carried on a belt and then ejected while the vision system snaps the part on the fly, which ensures the full and efficient inspection of the fastener.

“The BEGItech CLT machine is the perfect solution for parts such as screws, studs, shafts and bar turning. The accuracy of this system is 0.005mm and depends on the chosen vision hardware.”

Lazpiur has launched two versions of the BEGItech CLT machine. The first one is designed for small parts up to 20mm long; and the second version can handle larger parts with a scope of up to 50mm long.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.