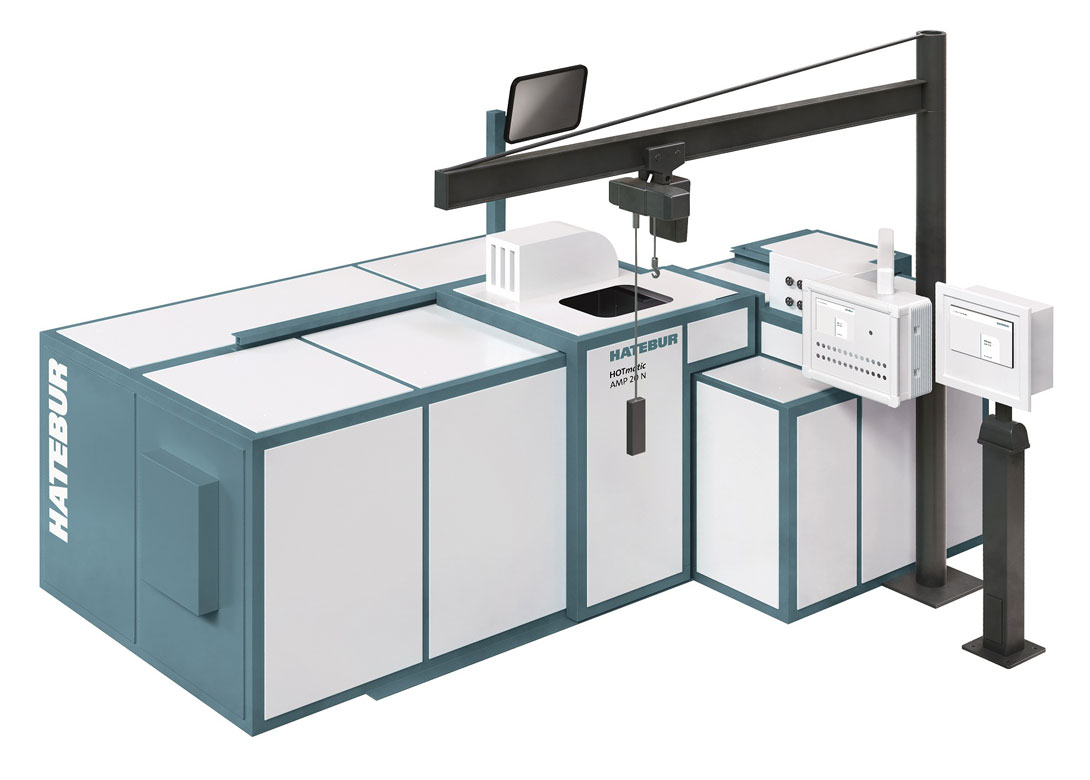

Hatebur has introduced the HOTmatic AMP 20 N, a machine specifically designed for the manufacturing of forged cam lobes, with the aim to improve the efficiency and productivity of suppliers in the automotive industry.

Thomas Christoffel, CEO of Hatebur, explains: “Almost all of the worldwide forged cam lobes are produced on Hatebur machines. With the development of the HOTmatic AMP 20 N, we can react to new trends in the industry. We want to make our customers even more productive and strengthen our market leadership.”

Thin cam lobes are the focus

Hatebur reports that, to date, most of the forged cam lobes are produced on two of its machines – HOTmatic AMP 30 S and 20 S – reliably and efficiently. “There is a trend towards thinner cam lobes in order to support the lightweight construction of engines,” says Thomas. “That is why the R&D division of Hatebur started with fundamental research on cam lobes with a thickness of 8mm instead of 12mm.”

Thomas continues: “The thinner cam lobes impose the highest demands on the forming machine – in particular in terms of the shearing quality, the pressing force and the part transfer. After conducting our research we introduced the HOTmatic AMP 20 N, which is ideal for thinner cam lobes with high surface quality, outstanding wear resistance and precise geometries.”

Precise, fast, efficient

Hatebur points out that the new HOTmatic AMP 20 N offers a total press load of 1,500kN, an impressive production speed and the highest precision. The machine body has been reinforced and guarantees the necessary stability.

“In three forming stations and with a maximum of 200 strokes per minute, the AMP 20 N produces cam lobes with an outer diameter of up to 48mm out of raw parts with 24g – 217g,” summarises Reinhard Bührer, head of marketing and sales at Hatebur.

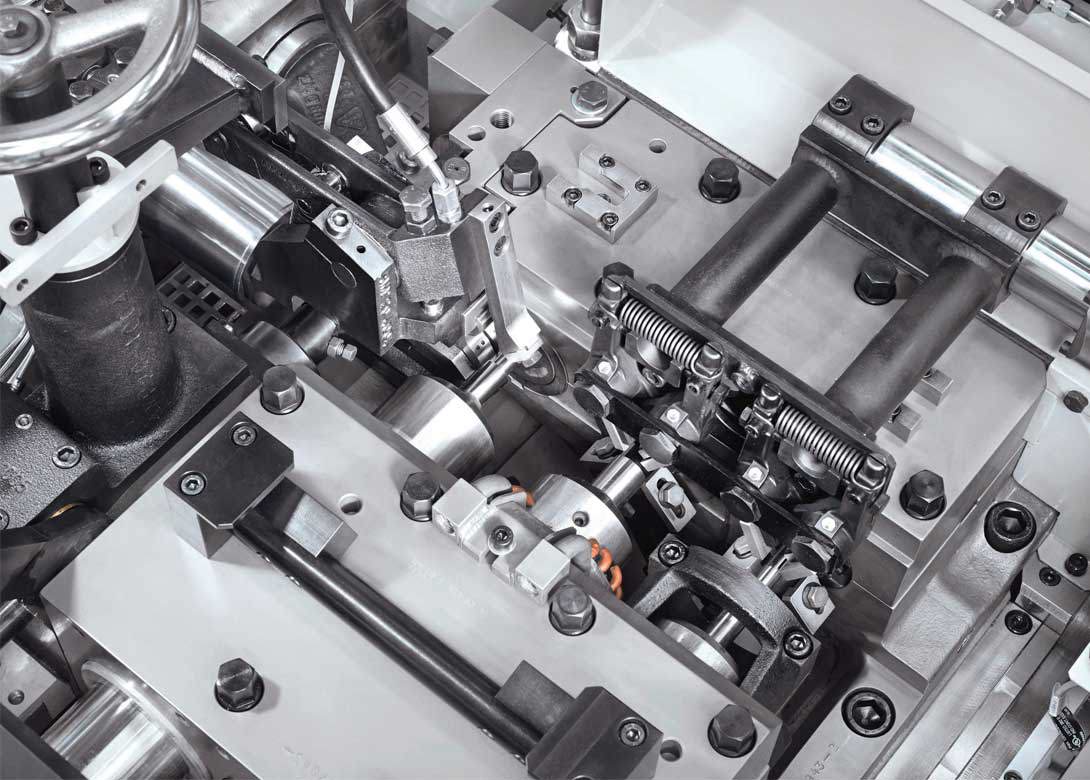

Up to 6 meters long and almost 1,200ºC hot, bars are brought exactly into position via four feeder rollers, powered by servo drives. “When thin parts are being processed, the transport between the forming stations needs utmost accuracy to achieve an ideal surface quality,” explains Reinhard. A central element of the machine is the shearing unit. “This is where parts with a cut-off length of 20mm – 45mm are made. Just as on other Hatebur machines, the surface quality of the shear plane is outstanding. The forming of the parts can start from the first station,” reports Reinhard.

More output and efficiency

Almost all customary cam sizes for passenger cars can be produced on the AMP 20 N. “Most of the tools are compatible with the HOTmatic AMP 20 S. Low maintenance and operating costs, as well as the high productivity lead to an exceptional cost benefit ratio,” says Reinhard.

While the AMP 20 N is an ideal machine for the production of forged cam lobes, it is not a single purpose machine, emphasises Thomas Christoffel: “The AMP 20 N is flexible and can be used in a wide variety of applications.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.