Fasteners, bolts and small parts with internal drives play a key role in industrial assembly processes when it comes to the secure fastening of components and assembly groups. Equally important is their corrosion protection – particulary in challenging areas of use. This is why EJOT, WMV and Dörken have joined forces to develop a technological innovation for applications in the dip spin process.

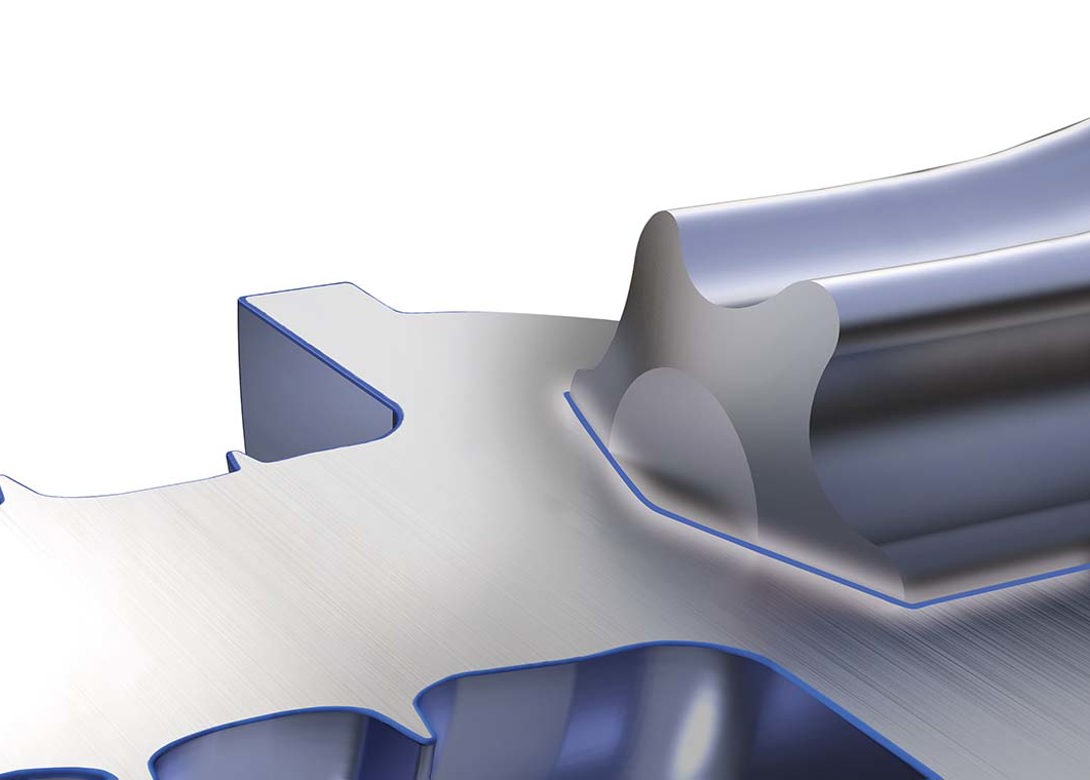

Whether it is in the automotive or telecommunications industries, medical technology, electronics or pneumatics – small fastening elements are used everywhere, just a few millimetres in size and typically featuring internal drives such as TORX® or TORX PLUS®. Providing these small fasteners with long-term protection against corrosion calls for a special zinc flake coating. However, fastening technology specialist EJOT saw room for improvement with the technology used thus far, with the company subsequently deciding to invest in its own coating centre of excellence.

Whether it is in the automotive or telecommunications industries, medical technology, electronics or pneumatics – small fastening elements are used everywhere, just a few millimetres in size and typically featuring internal drives such as TORX® or TORX PLUS®. Providing these small fasteners with long-term protection against corrosion calls for a special zinc flake coating. However, fastening technology specialist EJOT saw room for improvement with the technology used thus far, with the company subsequently deciding to invest in its own coating centre of excellence.

Together with Dörken and WMV, a new coating technology was developed at the EJOT site in Tambach-Dietharz, Thuringia, Germany, which enables very even and thin coating structures to be achieved. Corrosion expert Dörken supplies the part’s specific coating material to EJOT and was also involved in the planning of the project. This also applies to the third company in the alliance, the globally active manufacturer of coating plants, WMV.

State of the art technology

Together the companies identified an ideal, parts specific coating and developed a machine capable of coating 120kg material with a simultaneous position shifting at an acceleration of 32 g (g-force). The WMV PULZ® unit – a planet wheel, roller and coating centrifuge – for which a patent is pending – is used to coat items such as small parts with hollow spaces, as well as fasteners. Due to the high requirements on corrosion protection a zinc flake system from Dörken is used. Permanent rotation with simultaneously high acceleration level (32 g) results in the even, process safe and thin coating of the parts in the modern PULZ unit. This also benefits the environment, as the optimised coating process results in a reduction in CO2 emissions of around 30% compared to previous processes.

The project as a whole cost a great deal of time and effort for the companies involved, but all challenges could ultimately be overcome. How? By testing, experimenting and thinking outside of the box. “Innovation sometimes takes time. But with this project, we have not only developed a unique technological innovation, but also a really good partnership,” says Christos Tselebidis, sales director at Dörken.

Application engineering advantages

Dr Fabian Simonsen, operations manager at the Thermal and Surface Coating Centre at EJOT, is also delighted with the expansion of areas of application for small fasteners: “Finally, it is possible to also coat small, complex parts in a process safe manner, without clogging TORX or TORX PLUS drives. Our customers have waited a long time for this.”

This considerably improved product quality can now also be measured reliably. In contrast to the previous, improvised method of measuring the depth of penetration of the drive using a standard assembly bit, EJOT has enabled the use of gauge measurements for the bit penetration of TORX PLUS drive systems. This means that an objective method for checking the bit accessibility of zinc flake coated fasteners is available on the market for the first time.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.