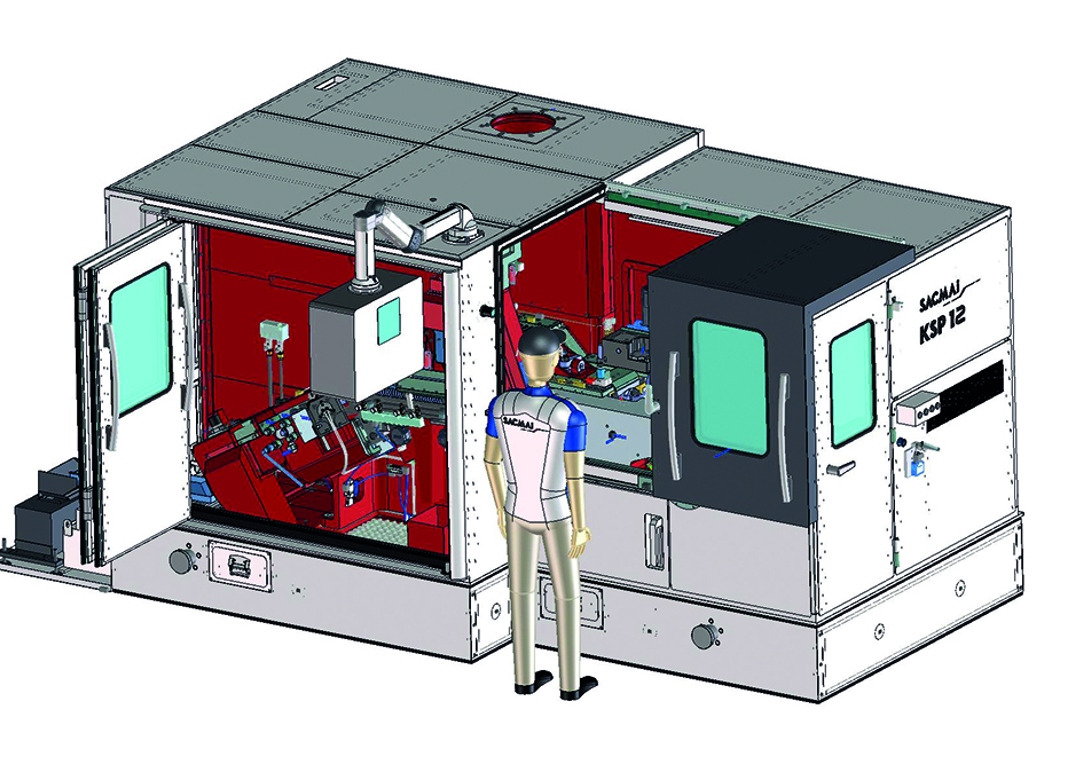

2021 will see the delivery of the first combined header model KSP12-R from SACMA Group, for fasteners from M3 to M8 – with a max shaft length of 60mm and an integrated threading station. The machine combines typical SACMA solutions with the most advanced mechatronic technology available.

The machine represents the new generation of the KSP11-R, featuring major set-up motorised adjustments for a quick and friendly changeover. These adjustments include an S-Feed wire feeder driven by torque motor; a motorised wire stock gauge and DKO; as well as a threading starter driven by torque motor with self-learning function borrowed from Ingramatic rollers.

The quality management is facilitated by two gates interfaced with the load monitoring system and discharging non-conforming parts respectively after the header and after the roller. An optional sophisticated load control system also protects the machine against overloads and monitors the forming and rolling processes. Scrap separators in different sizes are also available when producing self-tapping screws.

All these features, SACMA states, makes the KSP12-R an ideal investment when compared with running parts traditionally on a line of connected machines. In addition, when compared with a traditional line of connected machines the KSP12-R offers a utilisation of production floor space and consequently more parts can be produced per area – making the overall plant more profitable and efficient. Plus, in terms of maintenance, users would need more maintenance staff when purchasing independent machines. SACMA’s combined machine is one machine doing two operations, thus requiring only one machine to be maintained.

This new model is also more eco-friendly as it is a combined machine with the header and threader enclosed in one soundproof enclosure. This allows all coolant and oils to be recycled safely and controlled in one sealed area, meaning no oil leakage, less pollution and a clean and safe working place.

Also using only one motor for two operations is more efficient than numerous motors, as well as meaning only one machine needs to be fixed to the floor and connected to the air plant and power supply.

SACMA also points out that all its machines are recognised as ‘quick plug in’ equipment – after simply a few hours the KSP12-R is ready to start production.

SACMA Group is well known as a leader in designing and manufacturing combined headers to produce fasteners from M4 to M24. The combined headers are suitable to run fasteners and special automotive screws and bolts by producing the finished parts directly from wire. These machines have the forming, pointing and thread rolling processes all in one machine.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.