RLS Tooling investing in machinery and people

12 June 2017

The process of continual improvement and investment, throughout the organisation, is in the DNA of RLS Tooling – whether in machinery or in the development of people.

RLS Tooling Ltd believes this is just one of the reasons why it is amongst the leading thread rolling die manufactures worldwide. In addition to investing in the latest technology and machinery, RLS thinks it is also crucial to have the best people operating and maintaining this machinery. For this reason, in the last four years, RLS has taken on new apprentices each year. When the apprentices have finished their courses they are encouraged to proceed into further certifications. Last year RLS was honoured to receive the prestigious award for ‘Employer of the Year’ from In-Comm Training, acknowledging the company’s continual investment in apprentices.

In recent years RLS has invested heavily in new machinery and intends to continue this strategy throughout 2017 – having just placed an order for another new CNC profile grinding machine. This will enable it to increase production capacity and reduce delivery times to customers. In addition, RLS upgraded its contour measuring system to the latest CNC version at the end of the April.

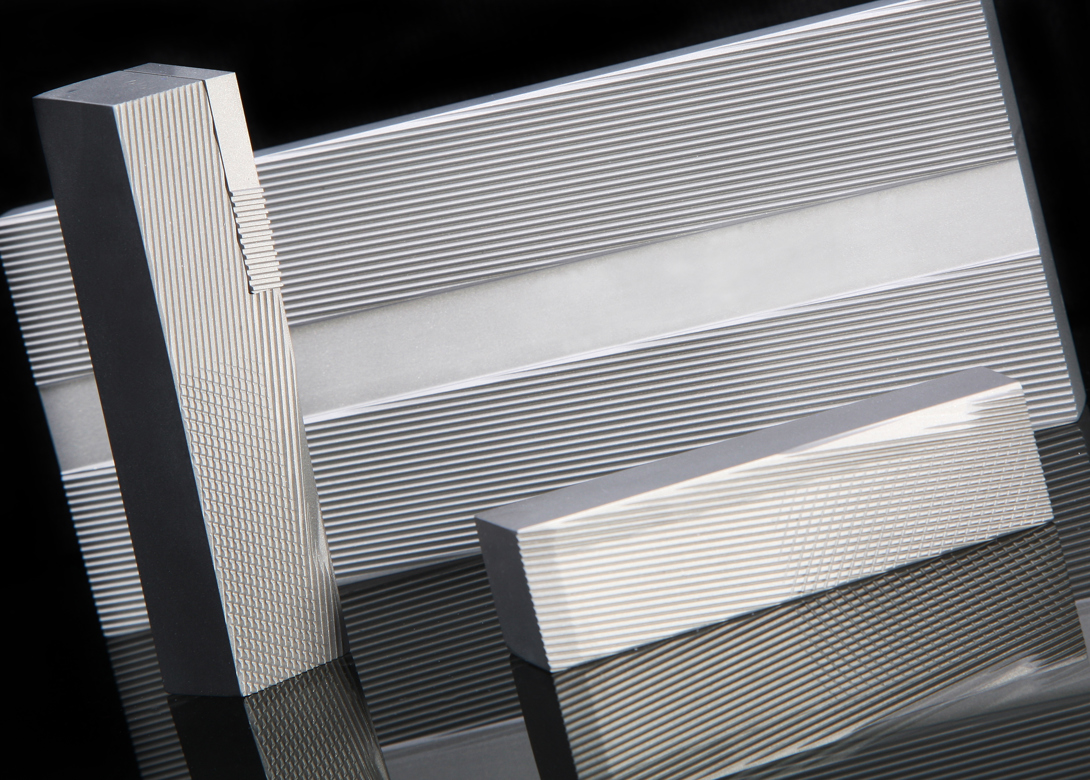

RLS manufactures a range of flat dies and circular thread rolls. To compliment these it is also proud to hold licences to manufacture dies for making Taptite®, Remform®, MAThread® and Excalibur Screwbolt® products. RLS also supplies tooling for rivet manufacturers, which can be supplied either normally multistack or Monobloc if required.

RLS holds in stock a range of ISO and Unified thread forms for the most commonly used thread rolling machines, but also holds specific stock for customers – who want the comfort of knowing that tooling is just a delivery away for those most important urgent orders.