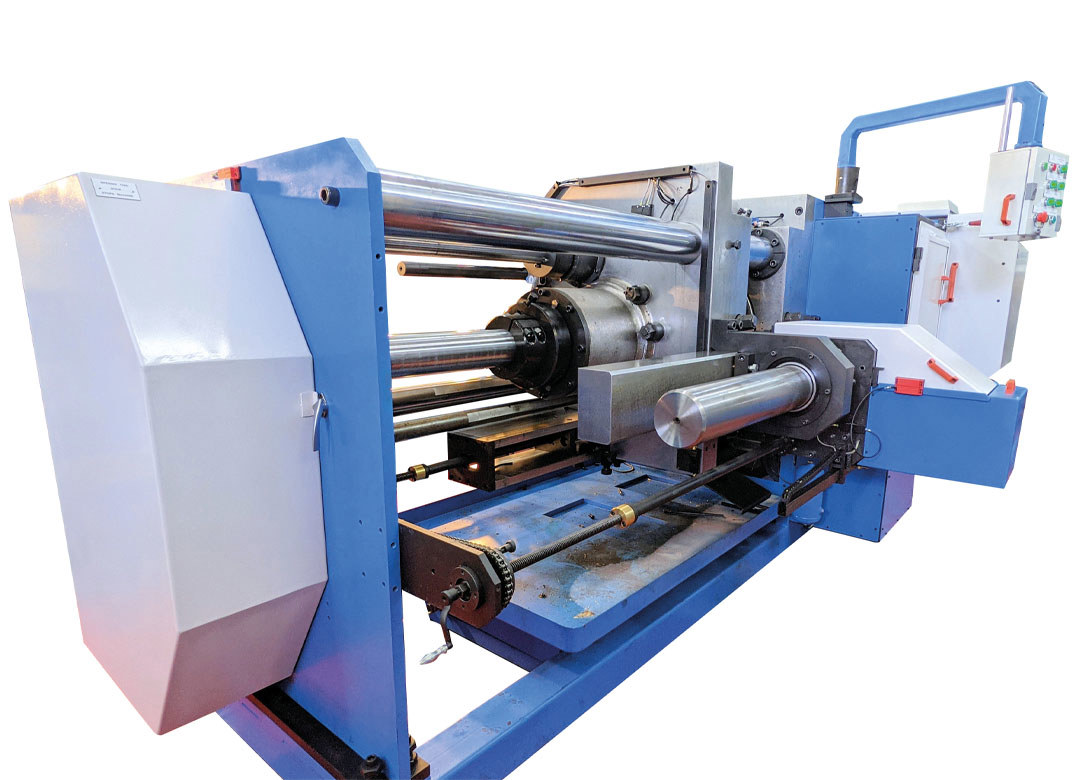

Videx Machine Engineering has been manufacturing machinery for U bolts, anchor bolts and eye bolts since 1973. The machines work from wire coil and perform all operations fully automatically.

Today’s market demands are small production batches, requiring short changeover times and operator friendly tooling. With that in mind, Videx has recently added the new line of VAS-DBQ machines that mean customers will no longer have to make bending dies for each part. The new machines are supplied with a floating bending die that covers the entire range of round and square bottom

U bolts, enabling customers to make new sizes of U bolts in minutes.

The VAS-DBQ models are equipped with a positive stripper system for the bending station, allowing the operators to run the machines at the fastest possible speed without risking parts jamming. The new Videx operator consoles also now include many of the instructions and messages that were previously included in the operator’s manual. Plus, the new computerised system makes the machine operation easier, intuitive and more operator friendly, enabling easily translation and altering of text to everyone’s language.

All new 2024 Videx models will be serviced by remote through a laptop that Videx will supply. The laptop includes all the software and drivers of the machine, including a remote access program that will be used by Videx engineers to service the machines.

The modular design of the machines enables Videx to add cold forming operations, such as heading and extrusion, as well as material removing operations, including chamfer cutting (pointing), chamfer rolling, form rolling, knurling, extrusion of the ends prior to thread rolling, collaring, heading, grooving, drilling, bending and flattening.

www.videx-machine.com/en

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.