At wire® Düsseldorf, WAFIOS Umformtechnik will be showing for the first time the new HC 6-80A rotor press with a direct connection to an EWMenn AF 61 thread rolling machine – using the patented PTS (Pneumatic Transport System).

WAFIOS Umformtechnik explains that forming machines with an integrated thread rolling unit, also known as combination machines, have recently made a comeback. However, the advantage of this type of machine, which allows production from the wire to the finished screw, with a small footprint, unfortunately also has considerable disadvantages. First and foremost, low flexibility, especially when changing over to a different range of parts at short notice.

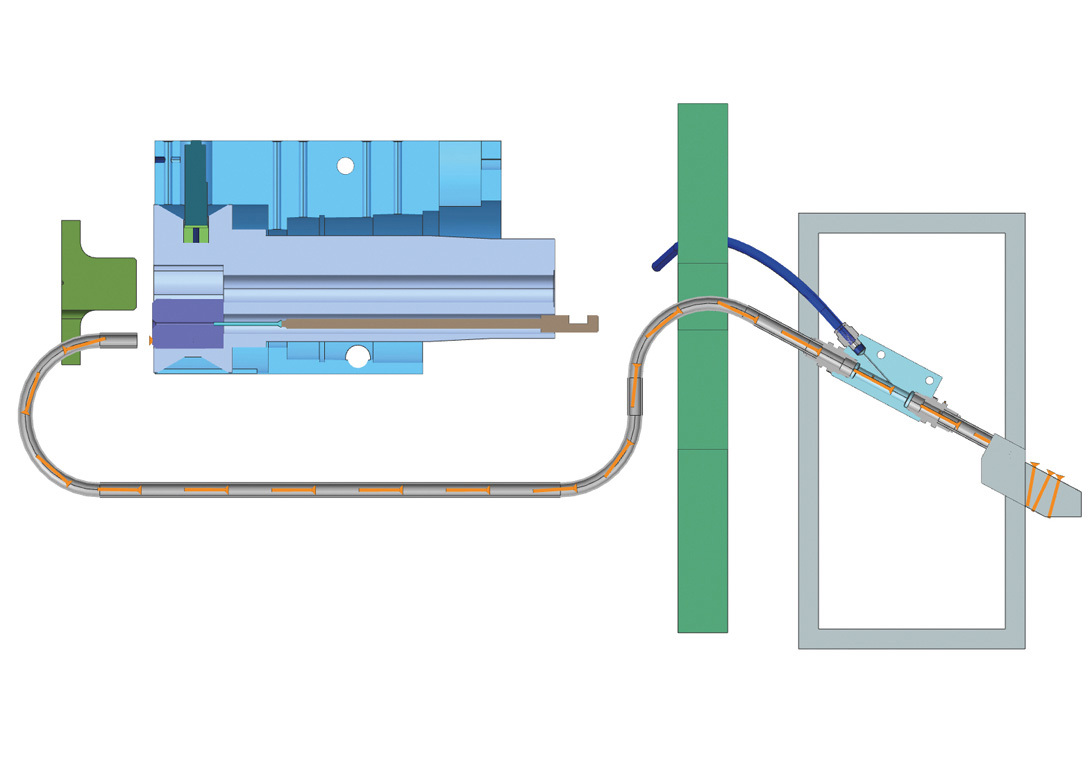

This gave the experts at WAFIOS Umformtechnik the idea of linking the newly developed HC 6-80A to an AF 61 thread rolling machine using the patented PTS, which was presented for the first time at the wire® 2022 show and is the central connection between the two machines – making the linking compact and flexible.

During production, the blanks pressed on the rotor press are removed directly from the die and transported via a pipe system out of the press to the desired location. In this case, directly into the feed rail of the roller.

Manufacturers of cold formed parts who have converted to the new PTS report several advantages, including the prevention of parts being mixed after changeover to another part type; as well as the avoidance of oil carry over – with the parts coming out of the machine almost ‘oil free’, which often eliminates the need for an additional parts washing operation. This is what makes direct connection to the rolling machine possible in the first place.

In addition, energy is saved for the conveyor belts, demagnetisers, and centrifuges, that are no longer required. One user was also able to reduce the amount of oil to be disposed of by up to 85%, thereby extending maintenance intervals. Compared to a normal ejection chute with a blast air nozzle, the same user was able to reduce compressed air consumption by over 30%. The PTS also helps fastener manufacturers to make significant progress in the increasingly important area of sustainability.

WAFIOS Umformtechnik also underlines that the new HC 6-80A itself is a further development of its proven rotor technology and also has a number of innovations included, such as the maximum length for screw blanks and other cold formed parts being increased for the first time to a previously not possible 80mm. Plus, there is a completely redesigned drive with clutch/brake combination. “In concrete terms, this means that the user has much more direct power during jogging operation because the clutch only engages when the engine is revving up and the machine has reached sufficient flywheel mass,” explains WAFIOS Umformtechnik. “For the first time one of our machines has also been equipped with the iQ Energy Monitoring function, which enables precise media consumption measurement and thus makes a further contribution to saving energy.”

The major advantage of WAFIOS Umformtechnik rotor technology, which has been tried and tested for decades, is its high-speed, which is unique in the double blow world. The company underlines that the newly developed HC 6-80A is no exception – producing 80mm long parts at speeds of up to 380 pieces per minute. “With this innovative direct connection between cold former, PTS and thread rolling machine, the WAFIOS Group is making its contribution to greater sustainability and competitiveness in the fastener industry,” states WAFIOS Umformtechnik.

The high performance AF 61 thread and profile rolling machine from EWMenn will also be presented on the joint exhibition stand – the machine manufacturer is also part of the WAFIOS Group.

www.wafios-umformtechnik.de/home.html

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.