Dr Peter Standring, technical secretary, Industrial Metalforming Technologies (IMfT)

The term ‘zero defects’ was coined by Quality Guru Philip Crosby in the mid 1960s whilst working on a US rocket programme. His aim; to reduce the number of failed launches. In essence, he sought to eliminate defects using quality management tools.

The major criticism and reason for its lack of wider adoption after 1970 was that perfection – or production without defects – is an impossibility.

Although attracting board room commercial interest the concept lay basically dormant until picked up by the US automotive industry around 1990. Here, it was seen as a counter to the all powerful Japanese auto invasion of the US market – based primarily on guaranteed quality and cost. Interestingly, much of the Japanese success was down to the adoption and exploitation of Total Quality Management (TQM) concepts, which US citizen W.L. Deming had been developing in post war Japan.

The statistical methods of process control used by Deming and others (including the early Ford Motor Co) were similar to the Six Sigma concept developed by Bill Smith at Motorola in the 1980s. The US$12 billion of savings announced in 1995 by Jack Welsh, CEO of General Electric, due to his company’s adoption of Six Sigma techniques produced a scramble by all dynamic companies to do the same. The result, the proliferation of quality management teams based in most manufacturing companies seeking, as in the case of health and safety, to have zero problems. It should be noted that the stock market fall from grace of many of these companies has been blamed on the lack of inventiveness, which statistical methods are claimed to foster.

This article will not seek to rehearse the arguments for quality management, that is well covered by the growing lexicon of acronyms on the topic. Rather, it will consider some of the areas of fastener manufacture where problems do arise and which can result in defects.

Definition of a defect

Just like the landscape, language is littered with words and phrases that mark an earlier time. A ‘dozen’ is perhaps an antiquated word not finding much modern day use but most folk would know that it means twelve of something. However, a ‘Baker’s Dozen’ meaning the number thirteen? It would be interesting to find out what percentage of English speakers know why medieval bakers in England gave their customers 13 rather than 12 loaves. The answer is simple; when the king of the day passed a law banning the sale of underweight bread on pain of severe punishment, a baker was happy to give an extra loaf away to comply with the law.

This may have been an expensive practice for medieval bakers but it is also true today in all manufacturing industries where the achievement of an actual size or value is problematic. Paper making is an example where the calendaring process produces a product the thickness of which changes post processing.

Reducing the excess product provided to meet the specification stated, by just a tiny percentage on high volume goods, be they sold for construction, food consumption, cosmetics or secondary manufacture, would have a major effect on a company’s bottom line. Just imagine one extra bean in every can and then multiply that by 109. As Bogart could have stated in the film Casablanca, one billion beans would surely make quite a hill!

But, you might very properly suggest, giving a product away to ensure it meets the required specification cannot be considered a defect? And yet, using the counter argument, if a coil of steel strip or rod was outside the size tolerance of what was specified, that surely would be considered defective?

As we enter the 2020s a significant problem that faces the online clothing market is that 40% of the goods sold are being returned, particularly by young people. Clearly, whilst most of the returned goods may not be defective in the way they were manufactured, the concept of returning goods to the retailer might spread across sectors and if it did, could create a supply chain problem downstream of manufacture. A UK fastener manufacturer informed me that only a few days earlier he had a batch of fasteners returned to his company and was surprised to find he was legally obliged to accept them.

Of course, the above does not describe what would be an evident product defect. Say a screw without a thread, a nut with a split or a washer without a hole. So, what is a defect and how could it commonly be described?

Defects

An aeroplane crashes and assuming it is not due to pilot, air traffic control error or criminal activity, then something else must have failed. On a new aircraft type, as with the early BOAC De Havilland Comet, repeated pressurisation and a stress raising window geometry design was identified as the cause of failure. The resulting design solution has been applied to all subsequent pressurised aircraft. This problem was quickly evidenced when multiple crashes occurred in the same aircraft type. However, a similar defect can also take place well into the functional life of an aeroplane. Both could be defects due to design but not evidenced until the in-service life has begun.

All OEMs can be plagued by such problems as can be noted by the product recalls they are forced into making. Clearly, as an OEM, they have responsibility for the product they manufacture. However, in today’s global environment, where supply chains often cross continents as well as national borders, following the audit trail may prove difficult particularly if the time to failure is long. This is why many industry suppliers are legally contracted to maintain legacy data for many years following use of the product. Security coding to identify the item is demanded in many safety critical applications and is essential for both the OEM and the supply base to mitigate any potential claims for damages.

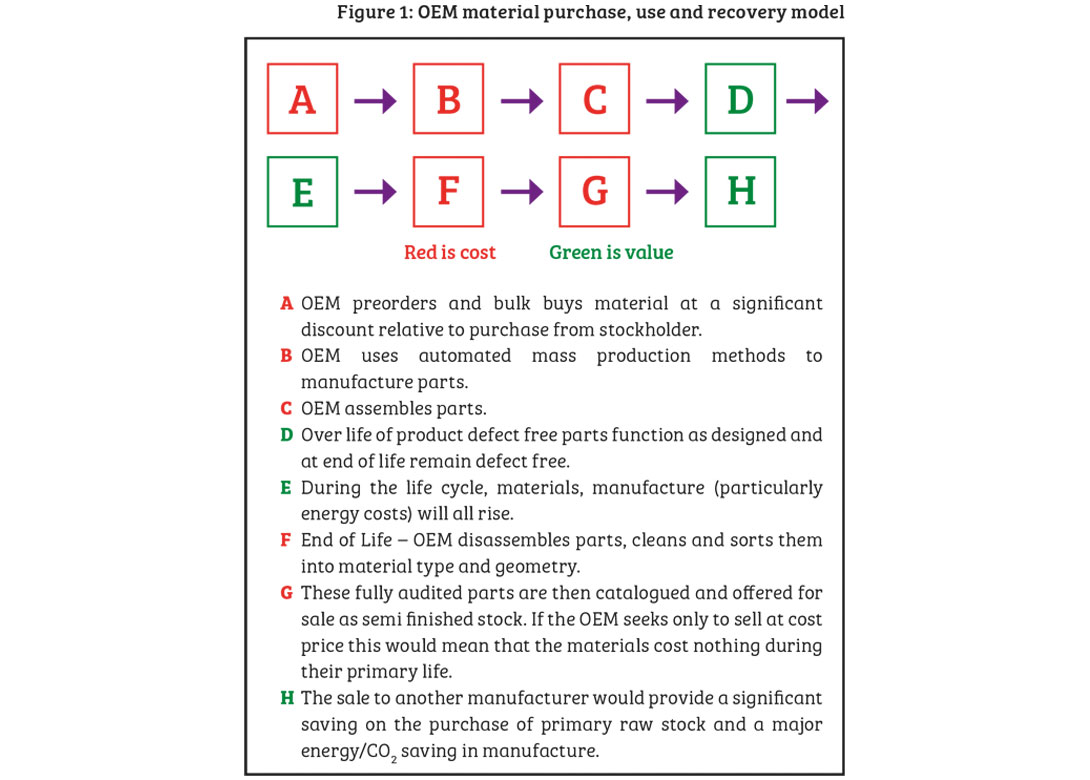

Clearly, at the end of life of the assembly, sub-assembly, whatever, virtually all items will remain defect free. Given that all OEMs should hold chapter and verse data on every single manufactured item, it is almost impossible to believe they don’t ‘harvest’ the invested value rather than selling the unwanted product for scrap. As shown in Figure 1, incorporating ‘disassembly’ into the product design, the OEM could resell fully audited materials and parts as semi finished items for alternative lower grade manufacture. Putting this simple concept into practice could provide massive cash returns to OEMs whilst slashing energy and environmental costs on new materials and processing for other manufacturers.

Obtaining defect free parts for reuse represents a significant and worthwhile challenge for OEMs and the fastener industry to pursue in order to make it happen.

Fastener manufacture

Many years ago, I attended a plenary meeting of the International Cold Forging Group (ICFG) and heard a presentation by a leading Japanese expert in the field. His company, a world leader, was intent on achieving ‘zero defect’ supply to their customers. Interestingly, he offered an in-house comparison between the quality produced by techniques of machining with those of cold forming.

Average parts per million (ppm) defects recorded in the machine shops were slightly above 20 whereas those produced during cold forming were between 2 and 3. Of course, he stated, it was not possible to produce ‘zero defects’ inside the manufacturing units. Therefore, all products required 100% inspection prior to despatch to ensure the customer did not receive any defects.

The term ‘you get what you pay for’ is well known and in some cases very true. In a fastener manufacturing company, if a new coil doesn’t run, often the first to be blamed is the material supplier. At a non-confidential technical session attended by fastener specialists, representing a number of different fastener manufacturing companies, when a coil didn’t run the agreed action was to turn it round and run it the other way.

This simple exercise, which in many cases appeared to work, suggests that during coil manufacture an issue relating to orientation can arise. After many years of enquiry, I have never received a satisfactory explanation as to the cause of this apparent phenomenon. Other issues relating to heat treatment, strain hardening due to coiling and shot blasting, together with the surface imperfections that result from processing the resulting stock, present potential sources of manufacturing defects.

Interesting work has and is being carried out to assess the effect and influence of the variability of elements within alloy steel. This has shown how although within tolerance, elemental variations can change a material’s performance characteristics at the metal forming stage. ‘Getting what you pay for’ is clear if the constituent elements of an alloy are toleranced more tightly in one type of steel than another. Although within specification, the variation in such properties can result in unintended material behaviour when subjected to deformation in a multistation close tolerance cold header.

As in any system, inefficiency or failure of one part will reduce or eliminate the success elsewhere. Surface finish of the work material and tooling, the lubricant and its condition, and indeed the machine tool and its setting, are all integral contributing factors. As are the methods used to record the performance data and control the output. The introduction of anything new to a system, which is running under control, is always a source of potential trouble. For example, when cold forming, a new tool could fail very early or continue until wear requires it to be exchanged.

When asked in a public meeting about the wear characteristics of their cold forming tools, a major player in the industry replied without any hint of embarrassment, that the tools the company used never lasted long enough to wear out. What they also added, was that when a tool did survive, the ‘patina’, which it developed as part of its surface modification due to high pressure and interfacial lubrication, was something to be prized. If such a tool needed to be reground thus destroying the ‘patina’ this, he stated, would cause serious consternation for the machine operator whose bonus depended on smooth and successful output.

Tooling and its design, especially where multistation progression is employed, is crucial in achieving success. However, without total control over all aspects of tool manufacture and maintenance, either in-house (preferable) or with a tool maker/heat treater in which there is complete confidence, major difficulties can exist. In one situation I was associated with, a company struggled to develop a new five station part as the punch in station four repeatably failed within one thousand parts.

A representative of a Taiwanese tool making company happened to call and was invited to supply the failing punch. This they did within seven days and the tool produced over 76,000 parts. The company’s outsourced investigation into the tool steel revealed it to be nothing special suggesting that its success was simply due to manufacture and heat treatment.

Conclusion

Those in the supply chain can only provide products that meet the specification of the design. The tighter the tolerance, the greater the accuracy and this will clearly attract a higher cost to produce. Specifying more than is needed to achieve the design function is just another way of wasting money.

For manufacturers in a supply chain, design is also an issue relating to matters concerning material condition, methods of manufacture, equipment, tooling, skills, etc. Each of these activities are areas where product defects could and will occur. So, for a supplier to guarantee to provide ‘zero defect’ products they must undertake 100% inspection and remove all defective items.

Clearly, for a product like a fastener this will only be carried out where the in-service function warrants it. In reality, this would be justified in safety critical cases, particularly those concerning life or death situations (e.g crucial aerospace applications).

However, it was not always so, during WWII when the automotive industry basically took over the mass manufacture of aircraft, the overriding goal was to produce output and to solve whatever problems arose away from the assembly line. This was clearly a policy where the means justify the end and which thankfully, is no longer admissible.

So, for manufacturing output to be defect free, it must include what is done today and what might happen tomorrow. Direct problems identified at the time of production can be removed by inspection. However, defects that occur during service due to faults in manufacture or the specification of an inappropriate product, these matters would be more difficult to deal with and could result in recall and litigation. A rigorous testing regime can and will assist in eliminating many of these but as always, at a cost in both time and money. As history teaches us, this doesn’t always happen as it should.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.